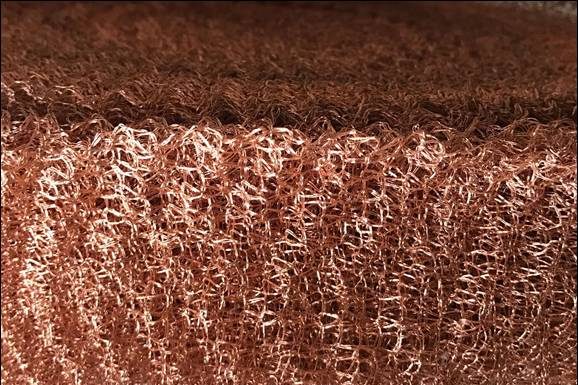

Discover the Key Features of Our Knitted Wire Mesh

Our knitted wire mesh stands out due to its unique combination of flexibility, strength, and precision engineering. Each product is crafted to meet rigorous industry standards, ensuring optimal performance in diverse applications. We provide solutions tailored to your specific needs, from filtration to shielding.

Exceptional Flexibility

High Filtration Efficiency

Superior Tensile Strength

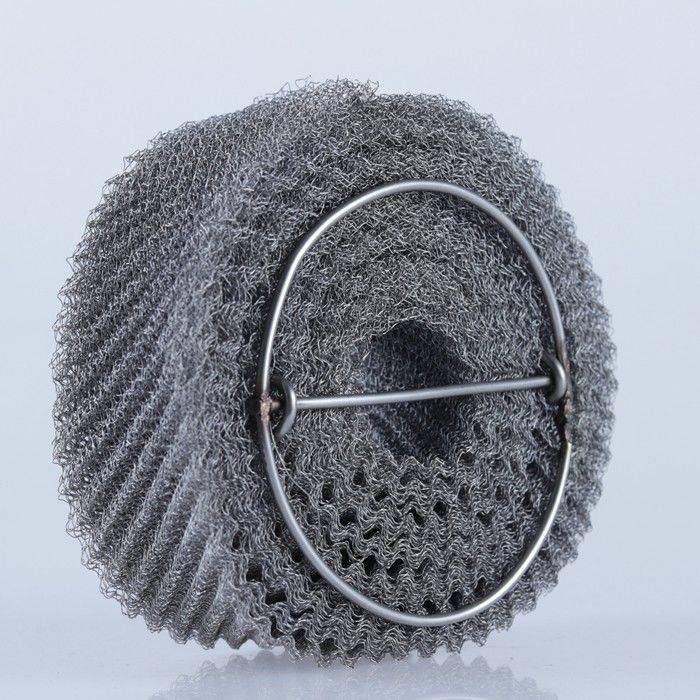

Knitted wire meshes are ideal damping elements to protect sensitive components from damage during operation. We have developed custom damping elements for many applications, including:

- Engines

- Turbines

- Automated production machines

In addition to the wire diameter, we precisely match the material, corrugation and dimensions to your process requirements.

- Wire diameter: 0.03 mm to 1.0 mm

- Size of mesh: 2.4 to 10 mm

- Knitted widths: 8 mm to 1,600 mm

Available versions include:

- Round or flat wire

- One or more threads

- Uncorrugated / slanted / arrow corrugated

Knitted wire mesh is a highly effective damping element, offering excellent vibration absorption, shock resistance, and noise reduction. Its flexible, interlocking structure protects sensitive components from damage during operation—even in harsh, high-stress environments. At Gerard Daniel, we design custom damping solutions with knitted wire mesh for demanding applications, including engines, turbines and automated machinery.

The performance of a knitted wire mesh depends heavily on its material properties, mesh density and form. Optimally matched, our three-dimensional knitted wire mesh ensures a high elasticity and resilience depending on the intended use. Other properties include:

- High temperature resistance

- Corrosion resistance

- Strength and durability

- Noise reduction

- All common steels and stainless steels

- Aluminum

- Special alloys (e.g., Monel and Inconel)

- Titanium

- Copper

- Various plastics (e.g., PP, PVDC, ETFE, PFA and PTFE)

- Fiber materials (e.g., glass fiber or carbon fiber)

- Precious metal (e.g., gold and silver)

- Nickel

- Filter technology

- Environmental and process engineering

- Bearing and damping elements/vibration decoupling

- Vandalism protection

- Silencer

- Heat- or thermal-isolation

- Sealing elements

- Separation applications

- Filling material to avoid death volume

- EMC applications