1. Architectural Mesh Is More Expensive Than Perforated Plate

Perforated plate, when looking just at the material, is in fact cheaper than architectural mesh. On average architectural mesh costs anywhere from $15 to $35 per square foot whereas perforated palate only costs $5-$10 per square foot.

With that, the cost of a fully installed wire mesh system is substantially cheaper than a perforated plate system. This difference in this cost comes down to the fact the perforated plate systems require intricate framing.

The downfall of these framing systems is that they require more material and labor than architectural mesh mounting.

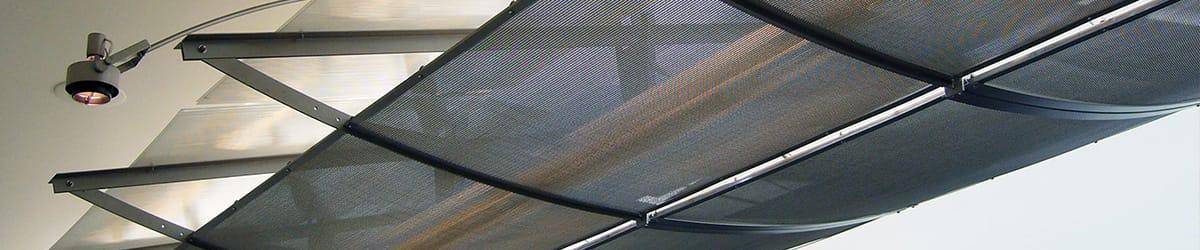

2. Architectural Mesh Can Be Placed Onto Any Substructure

Architectural mesh is a great design solution as it can be tensioned over the height of the project. However, adequate substructures must be put in place to absorb the significant loads the mesh creates (1400-1800 lbs per linear ft.).

Substructure frames are generally hot-dipped galvanized 6 x 6 x ½” L profiles.

Failure to integrate substantial substructure can result in the mesh system damaging to the building.

3. There Are Standard Sizes and Shapes

There is no standardization of architectural mesh specifications. In fact, the only aspect that can be considered standardized are the patterns of a specific weave type.

Elements such as the dimensions, quantities, and alloy are all customized based on the drawings you submit. This also means architectural mesh panels are made-to-order and typically not stocked.

It should be taken into consideration that lead times for architectural mesh are longer than other materials that are less custom, taking around 4 to 16 weeks to arrive.

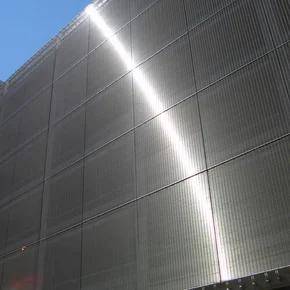

4. Architectural Mesh Looks the Same, Day or Night

Architectural mesh’s visual qualities can be very dynamic, changing based on the weather and time of day.

When in direct sunlight, it glistens and appears opaque. That said, on days of heavy overcast, the mesh openings of the panels become visible.

When nightfall arrives, each panel becomes transparent when backlit from the lighting of the garage.

5. Paint Doesn't Adhere To Stainless Steel Mesh

When stainless steel architectural mesh is painted , automotive-grade paint including a primer, bottom coat, and topcoat is applied. This leaves you with a thorough level of adhesion throughout the painted mesh panels.

Automotive-grade paint is also known for its elasticity. This means the paint will not chip or crack during shipment.

That said, if unwanted graffiti is applied to your architectural mesh system, it will not adhere and can power washed away with ease.

Architectural mesh is one of the most unique design materials on the market, providing structures will a one-of-a-kind aesthetic. Whether you utilize wire mesh, cable mesh, fine mesh, or specialty mesh each wire mesh system has the ability to provide sun protection, branding opportunities, and fall protection.

With an average price range of $15 to $30, architectural mesh can be customized to accommodate any budget while capturing the vision of the architect.

As most architectural mesh systems are constructed out of stainless steel, there is virtually no maintenance needed other than occasional power washing when subjected to graffiti. Best of all, every architectural mesh system is designed to last the lifetime of the structure making it the ultimate architectural design solution.