Explained

The ASTM A641 standard ensures superior quality and corrosion resistance in zinc-coated carbon steel wire, crucial for diverse applications.

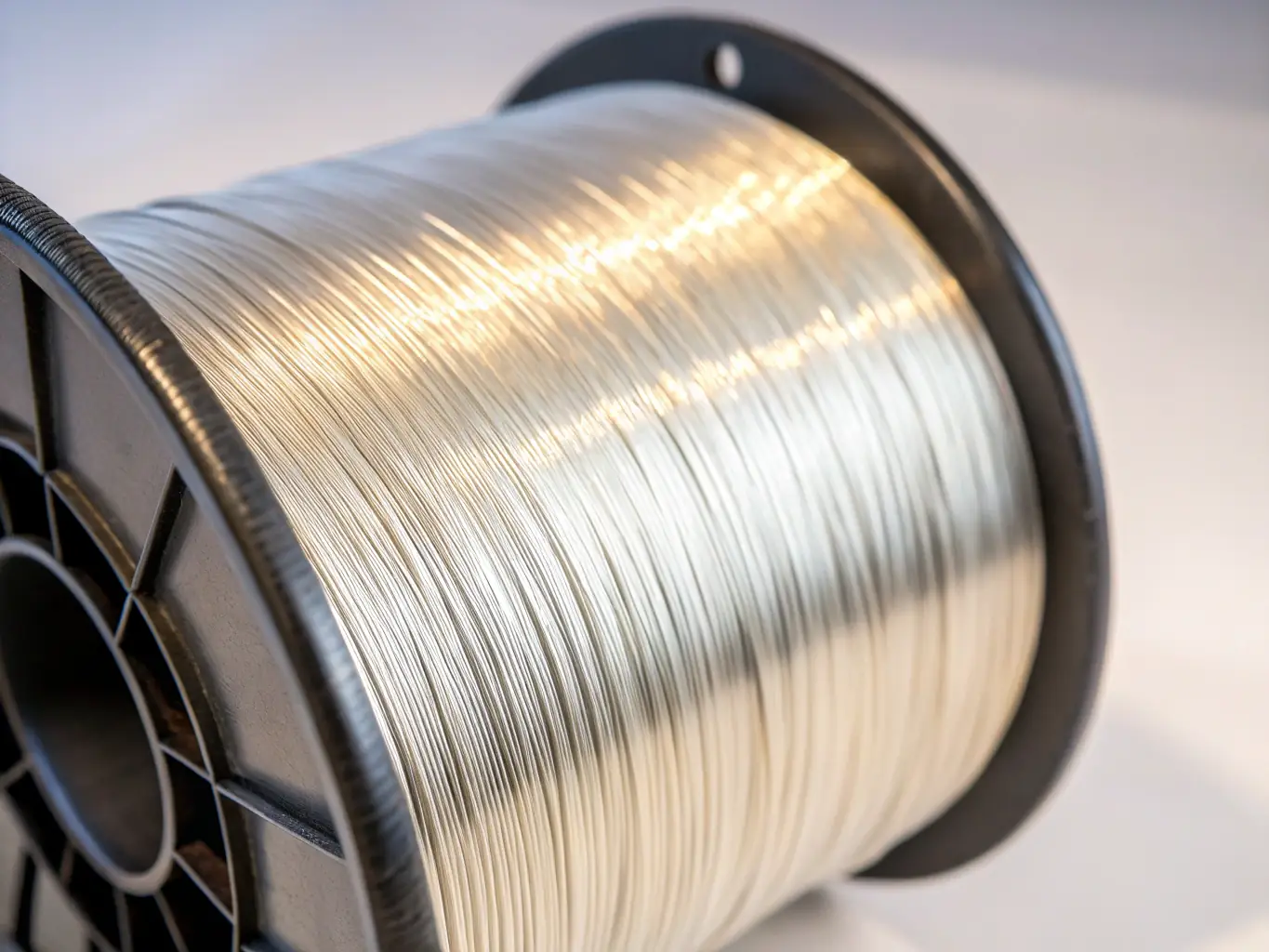

This specification covers the soft, medium, and hard temper zinc-coated (galvanized) carbon steel wire in coils for general use.

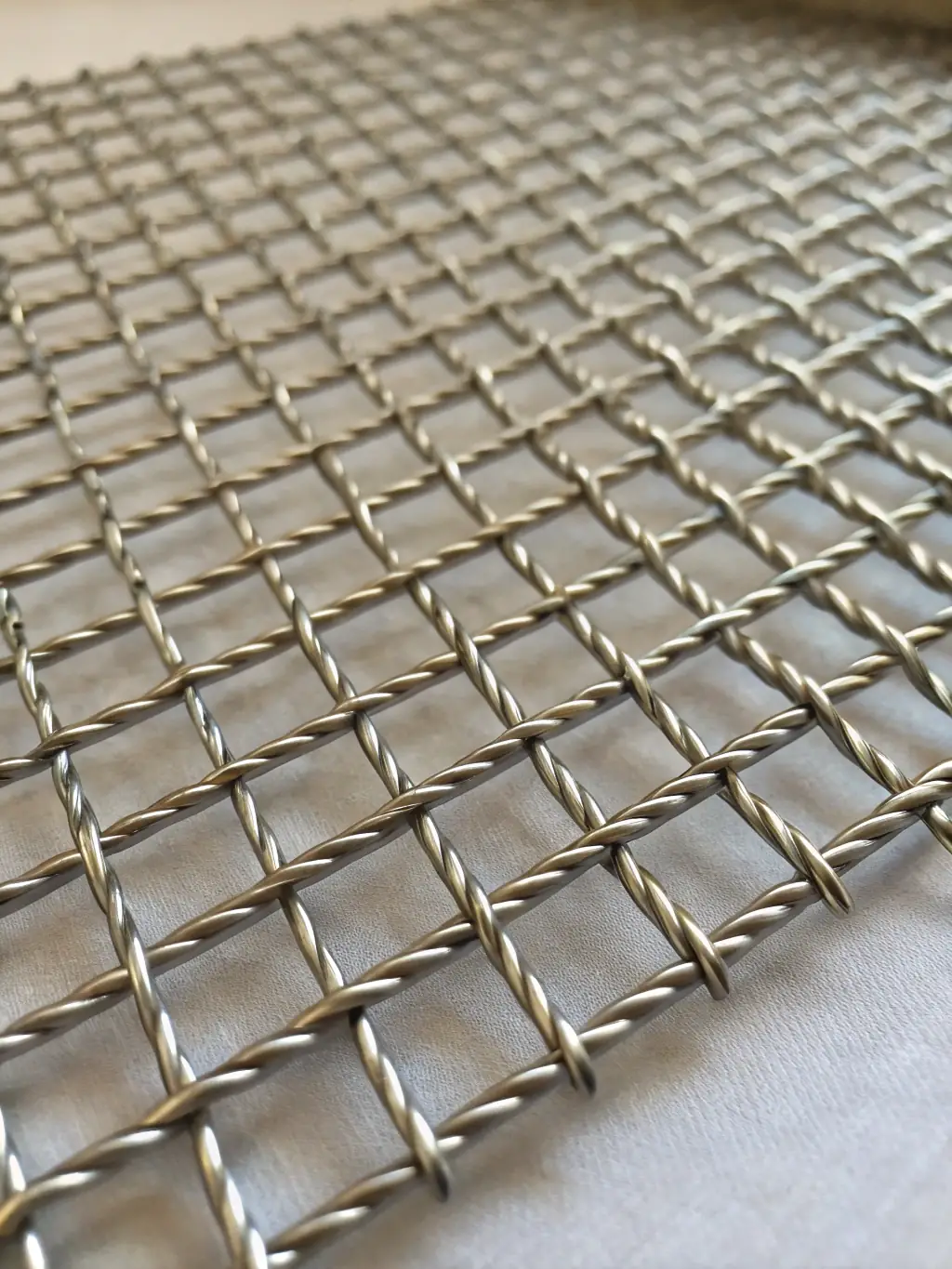

The steel shall be made by any commercially accepted steel making process. The material shall conform to the tensile strength requirements specified. The zinc-coated wire shall conform to the requirements for minimum weight of zinc coating of the specified class. Zinc-coated wire produced as “regular coating” shall have the full surface covered with zinc, but there is no specified minimum weight of coating.

What is

ASTM A641 is a standard specification for zinc-coated (galvanized) carbon steel wire. It covers requirements for various properties, including tensile strength, coating weight, and adherence, ensuring quality and durability in diverse applications.

Why Important?

Adhering to ASTM A641 ensures that the galvanized steel wire meets specific quality benchmarks. This is crucial for applications where corrosion resistance and structural integrity are paramount, providing reliability and longevity.

Rust Protection 101

Explore the Diverse Grades

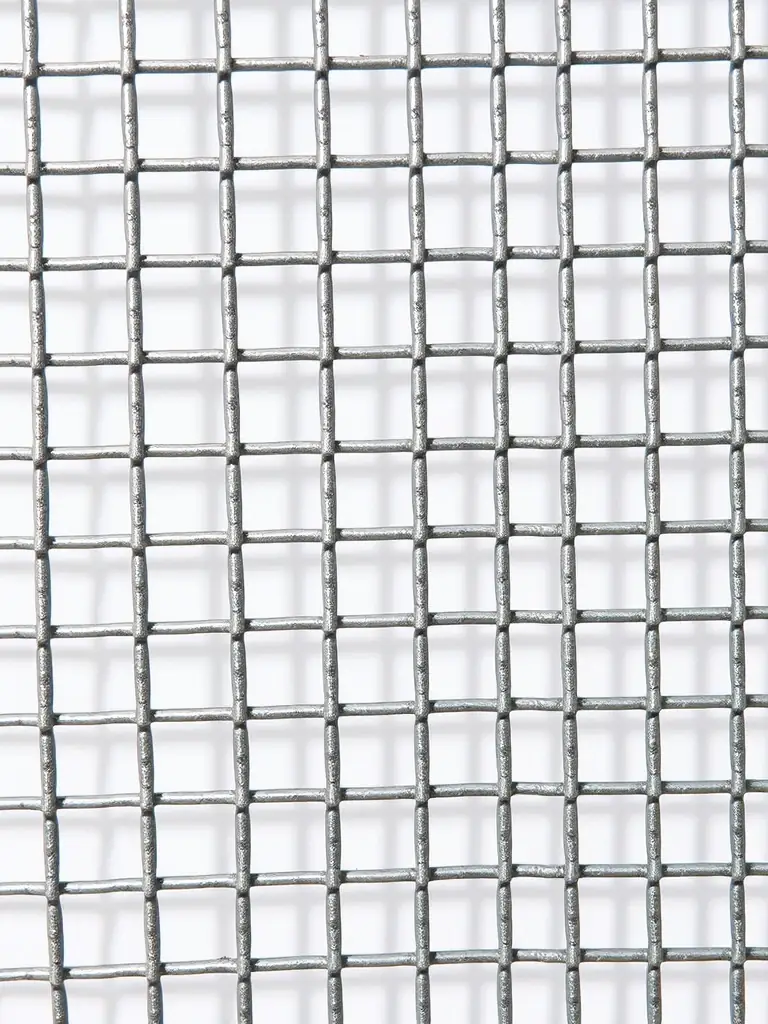

ASTM A641 galvanized steel wire comes in various grades, each tailored for specific applications. Understanding these differences is crucial for selecting the right material for your project, ensuring optimal performance and longevity. We provide detailed specifications and use-case scenarios to guide your choice.

Increasing Zinc Coating, Increasing Protection

Choose wisely based on application and environment.

Protection in Different Environments

Class 1 Mild Environment

Class 3 Medium Environment

Class 5 Harsh Environment

Class C Extreme Environment

Coating Class Guidelines

Class 1: Basic protection for general use

Class 3: Enhanced protection for moderate conditions

Class 5: Heavy-duty protection for challenging environments

Class C: Maximum protection for extreme conditions

| Wire Diameter in. | Class 1 Coating, oz/ft² | Class 3 or A Coating, oz/ft² | Class 4 Coating, oz/ft² | Class B Coating, oz/ft² | Class 5 Coating, oz/ft² | Class C Coating, oz/ft² |

|---|---|---|---|---|---|---|

| 0.035 | 0.15 | 0.45 | n/a | 0.9 | n/a | 1.35 |

| 0.041 | 0.15 | 0.5 | n/a | 1 | n/a | 1.5 |

| 0.048 | 0.15 | 0.55 | n/a | 1.1 | n/a | 1.65 |

| 0.054 | 0.2 | 0.6 | n/a | 1.2 | n/a | 1.8 |

| 0.062 | 0.2 | 0.65 | n/a | 1.2 | n/a | 1.8 |

| 0.072 | 0.2 | 0.65 | n/a | 1.2 | n/a | 1.8 |

| 0.076 | 0.25 | 0.7 | 1.2 | 1.4 | 2 | 2.1 |

| 0.08 | 0.25 | 0.7 | 1.2 | 1.4 | 2 | 2.1 |

| 0.092 | 0.28 | 0.75 | 1.2 | 1.5 | 2 | 2.25 |

| 0.099 | 0.28 | 0.8 | 1.2 | 1.6 | 2 | 2.4 |

| 0.106 | 0.3 | 0.8 | 1.2 | 1.6 | 2 | 2.4 |

| 0.12 | 0.3 | 0.85 | 1.2 | 1.7 | 2 | 2.55 |

| 0.135 | 0.3 | 0.85 | 1.2 | 1.7 | 2 | 2.55 |

| 0.148 | 0.35 | 0.9 | 1.2 | 1.8 | 2 | 2.7 |

| 0.162 | 0.35 | 0.9 | 1.2 | 1.8 | 2 | 2.7 |

| 0.177 | 0.44 | 0.9 | 1.2 | 1.8 | 2 | 2.7 |

| 0.192 | 0.5 | 1 | 1.2 | 2 | 2 | 3 |

| 0.207 and larger | 0.53 | 1 | 1.2 | 2 | 2 | 3 |

| Wire Diameter, mm | Class 1 Coating, g/m² | A Class 3 or A Coating,g/m² | Class 4 Coating,g/m² | Class B Coating,g/m² | Class 5 Coating, g/m² | Class C Coating, g/m² |

|---|---|---|---|---|---|---|

| 0.20 to under 0.25 | 20 | |||||

| 0.25 to under 0.40 | 25 | |||||

| 0.40 to under 0.50 | 30 | |||||

| 0.50 to under 0.60 | 35 | |||||

| 0.60 to under 0.80 | 40 | |||||

| 0.80 to under 1.10 | 45 | |||||

| 1.10 to under 1.50 | 55 | |||||

| 1.50 to under 1.90 | 65 | |||||

| 1.90 to under 2.30 | 75 | |||||

| 2.30 to under 3.20 | 85 | |||||

| 3.20 to under 4.00 | 100 | |||||

| 4.00 to under 4.90 | 115 | |||||

| 4.90 to under 5.90 | 150 | |||||

| 5.90 and over | 190 | |||||

| 0.9 | 137 | n/a | 275 | n/a | 412 | |

| 1 | 153 | n/a | 305 | n/a | 458 | |

| 1.2 | 168 | n/a | 336 | n/a | 504 | |

| 1.4 | 183 | n/a | 366 | n/a | 549 | |

| 1.6 | 198 | n/a | 366 | n/a | 549 | |

| 1.8 | 198 | n/a | 366 | n/a | 549 | |

| 1.9 | 214 | 366 | 427 | 610 | 641 | |

| 2 | 214 | 366 | 427 | 610 | 641 | |

| 2.3 | 229 | 366 | 458 | 610 | 687 | |

| 2.5 | 244 | 366 | 488 | 610 | 732 | |

| 2.7 | 244 | 366 | 488 | 610 | 732 | |

| 3 | 259 | 366 | 519 | 610 | 778 | |

| 3.4 | 259 | 366 | 519 | 610 | 778 | |

| 3.8 | 275 | 366 | 549 | 610 | 824 | |

| 4.1 | 275 | 366 | 549 | 610 | 824 | |

| 4.5 | 275 | 366 | 549 | 610 | 824 | |

| 4.9 | 305 | 366 | 610 | 610 | 915 | |

| 5.3 and larger | 305 | 366 | 610 | 610 | 915 |

Temper Controls: Stiffness, Strength, Flexibility, Durability; From Soft to Hard.

Soft Temper

Medium Temper

Hard Temper

| Wire Diameter, in. | Soft, Ksi | Medium, Ksi | Hard, Ksi |

|---|---|---|---|

| 0.035 to under 0.080 | 75 max | 70 to 100 | 90 to 120 |

| 0.080 to under 0.106 | 75 max | 70 to 95 | 85 to 115 |

| 0.106 to 0.176, incl | 70 max | 65 to 90 | 80 to 110 |

| Over 0.176 | 70 max | 60 to 85 | 75 to 105 |

| Wire Diameter, mm | Soft, MPa | Medium, MPa | Hard, MPa |

|---|---|---|---|

| 0.20 to under 2.00 | 515 max | 485 to 690 | 620 to 825 |

| 2.00 to under 2.50 | 515 max | 485 to 655 | 585 to 795 |

| 2.50 to under 4.70 | 485 max | 450 to 620 | 550 to 760 |

| 4.70 and over | 485 max | 415 to 585 | 515 to 715 |

| Wire Diameter, in. | Regular and Class 1 Coating | Class 3, 4, 5 or B and C Coating |

|---|---|---|

| 0.035 to under 0.076 | 0.002 | 0.002 |

| 0.076 to under 0.148 | 0.003 | 0.004 |

| 0.148 to 0.250, incl. | 0.003 | 0.004 |

| Over 0.250 to 0.500, incl. | 0.003 | 0.005 |

| Wire Diameter, mm | Regular and Class 1 Coating | Class 3, 4, 5 or A, B, and C Coating |

|---|---|---|

| 0.20 to under 1.90 | 0.05 | 0.05 |

| 1.90 to under 3.70 | 0.08 | 0.1 |

| 3.70 to under 5.90 | 0.08 | 0.1 |

| 5.90 and over | 0.08 | 0.13 |

ASTM A641/641M: Ensuring Quality in Galvanized Steel Wire

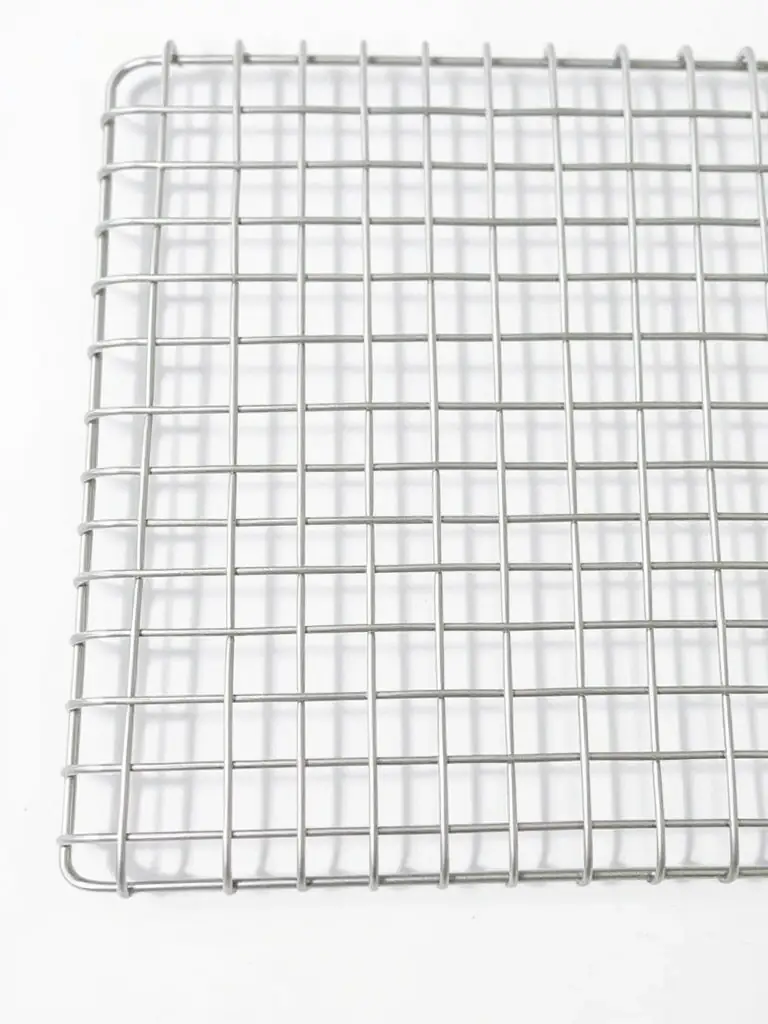

Mutual Metal Co., Ltd. adheres strictly to the ASTM A641 standard, ensuring our galvanized steel wire meets the highest quality and performance benchmarks. Our products are manufactured with precision, offering superior corrosion resistance and durability for diverse applications. We are committed to providing reliable and consistent products.

- Material Compliance: Adherence to chemical composition requirements.

- Coating Specifications: Uniform zinc coating for optimal corrosion protection.

- Testing Methods: Rigorous testing to ensure mechanical properties and coating quality.

Class 1 Galvanized Wire