Choosing the right woven wire mesh is essential for performance, efficiency, and longevity—whether you’re filtering fine powders in a pharmaceutical plant, reinforcing concrete, or designing an architectural screen. With countless variables like material, weave type, mesh count, and wire diameter, selecting the optimal mesh can feel overwhelming.

In this guide, we’ll walk you through the key factors to consider so you can confidently choose the woven wire mesh that meets your technical and operational needs.

1. Define Your Application First

Start by asking: What is the mesh supposed to do?

Common functions include:

- Filtration/Sieving (e.g., in chemical processing or food production)

- Screening/Classification (e.g., mining or aggregate separation)

- Reinforcement (e.g., stucco or plaster support)

- Shielding or Ventilation (e.g., EMI shielding, HVAC grilles)

- Decorative Use (e.g., interior partitions or façade cladding)

Your application dictates critical requirements like pore size, strength, corrosion resistance, and cleanability.

Example: A brewery filter needs food-grade stainless steel with fine openings to trap yeast, while a rock screener at a quarry demands coarse, high-tensile carbon steel mesh.

2. Choose the Right Material

The base material affects durability, chemical compatibility, and cost:

| Material | Key Properties | Common Uses |

|---|---|---|

| Stainless Steel 304 | Good corrosion resistance, weldable | Food, pharma, general filtration |

| Stainless Steel 316 | Superior corrosion resistance (with Mo) | Marine, chemical, high-salinity env. |

| Carbon Steel | High strength, low cost | Construction, industrial screening |

| Nickel Alloys | Heat & corrosion resistance | Petrochemical, aerospace |

| Copper/Brass | Conductive, antimicrobial, decorative | EMI shielding, architectural accents |

⚠️ Tip: Always verify chemical compatibility using a corrosion resistance chart—especially in acidic or alkaline environments.

3. Understand Weave Types

The weave determines mesh stability, open area, flexibility, and filtration efficiency. The four most common types:

✅ Plain Weave

- Each warp wire passes alternately over and under weft wires.

- Best for fine meshes (high mesh counts).

- Limited flexibility but excellent stability.

- Ideal for precision filtration.

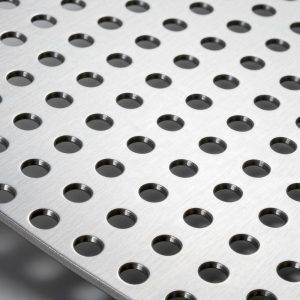

Caption: Plain weave – tight, uniform structure for fine filtration.

✅ Twill Weave

- Warp wires pass over two and under two weft wires, creating a diagonal pattern.

- Higher flexibility and strength than plain weave.

- Suitable for heavier wires and coarser meshes.

- Great for vibrating screens or rugged industrial use.

Caption: Twill weave – enhanced durability for demanding applications.

✅ Dutch Weave

- Fine weft wires packed tightly against coarse warp wires.

- Extremely low permeability; excellent for sub-micron filtration.

- Not reversible (one side is smooth, the other rough).

- Common in fuel, oil, and hydraulic filters.

Caption: Dutch weave – dense construction for high-efficiency filtration.

✅ Reverse Dutch Weave

- Opposite of Dutch: coarse weft, fine warp.

- High pressure tolerance with controlled flow.

- Used in high-pressure filtration systems.

4. Determine Mesh Count and Wire Diameter

- Mesh Count: Number of openings per linear inch (e.g., 100 mesh = 100 holes per inch).

- Wire Diameter: Thickness of individual wires (measured in microns or gauge).

These two parameters define:

- Opening Size (aperture)

- Open Area % (affects flow rate)

- Strength and Durability

Use this formula to estimate open area:

Open Area (%)=(Mesh Opening+Wire DiameterMesh Opening)2×100

📏 Pro Advice: For critical filtration, request certified test reports (e.g., per ASTM E11 or ISO 3310) to verify aperture accuracy.

5. Consider Environmental & Operational Factors

Ask yourself:

- Will the mesh be exposed to high temperatures? (Check material melting points)

- Is it in constant contact with water, acids, or solvents?

- Does it need to be cleaned frequently? (Smooth finishes like electropolished stainless are easier to sanitize)

- Will it undergo mechanical stress or vibration? (Twill or crimped weaves offer better fatigue resistance)

6. Don’t Forget Post-Treatment Options

Surface treatments can enhance performance:

- Electropolishing: Removes burrs, improves corrosion resistance (ideal for sanitary applications)

- Annealing: Softens the mesh for better formability

- Passivation: Boosts stainless steel’s natural oxide layer

Final Checklist: Questions to Ask Before Ordering

✅ What is the required particle retention size?

✅ What material compatibility is needed?

✅ What weave type best balances strength and flow?

✅ What are the operating temperature and pressure ranges?

✅ Do I need certifications (e.g., FDA, 3A, RoHS)?

Conclusion

Selecting the right woven wire mesh isn’t just about “hole size”—it’s a strategic decision that impacts system efficiency, maintenance costs, and product quality. By clearly defining your needs and understanding how material, weave, and geometry interact, you can pinpoint the ideal mesh for your project.

When in doubt, consult a trusted supplier with engineering support. Many offer free samples and application reviews—because the best mesh isn’t the cheapest one, but the one that performs flawlessly in your environment.