ISO 9044 Explained

Purpose

This standard defines terms and specifies requirements, maximum permissible error, and test methods for industrial woven wire cloth, with square apertures, used in screening and filtration.

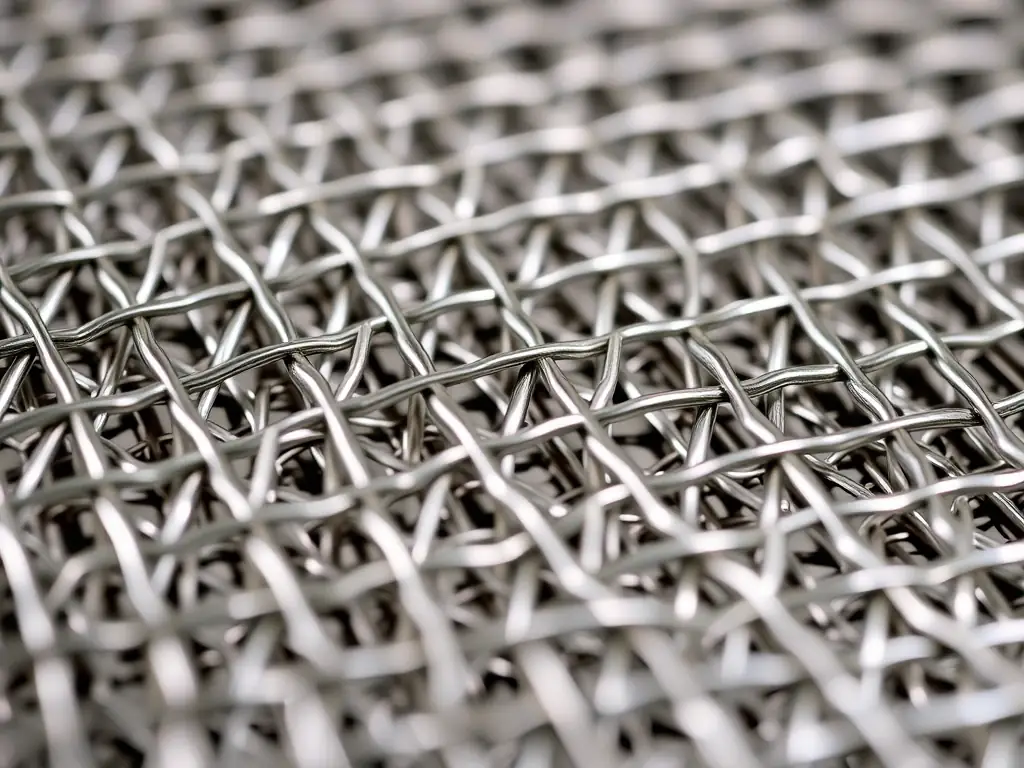

Material

This applies to industrial woven wire cloth made from steel, stainless steel, or non-ferrous metals. It excludes coated woven wire cloth and pre-crimped or welded wire screens covered in ISO 4783-3 and ISO 14315.

Requirements

Acceptable Imperfections: Major Blemishes

Smash: A complex break-up of the weaving pattern.

Burst: A tear of variable length in the cloth arising from unsustainable tension

during weaving. (Bursts normally occur near the edges.)

Broken shot (weft): A wide aperture or a line of wide apertures left when a broken weft wire

partly blocks the laying of the next weft wire.

Variation in weft count: Irregular weft count over a certain length of the woven wire cloth.

Draw-over: A certain length of cloth containing no weft wires.

Slack shot (weft) or loop: A weft wire which is longer than the neighbouring weft wires.

Creeper: A warp wire which is longer than the neighbouring warp wires.

Reed mark (tramline): Single line of apertures of excessive width in the warp direction.

Major Blemishes

- Oversized apertures

- Tears in the mesh

- Broken or missing wires

- Significant surface defects

Minor Blemishes

- Small surface scratches

- Minor variations in wire thickness

- Slight deviations in aperture size

- Other non-critical imperfections

The maximum number of major weaving blemishes (see Annex A), in any roll or roll piece of wire cloth shall not exceed the values given in below.

| Nominal aperture width, w, mm | Maximum number of major blemishes per 10 m² |

|---|---|

| 1 ≤ w ≤ 16 3 | 3 |

| 0,125 ≤ w < 1,0 | 4 |

| 0,063 ≤ w < 0,125 | 5 |

| w < 0,063 | 6 |

1. The maximum permissible error on width, of trimmed wire cloth rolls and roll lengths, shall be 0/+2 % of nominal.

2. The maximum permissible error on length and width, of square and rectangular pieces, shall be the larger of ±0,5 % or ±1 pitch.

3. For cut-to-size pieces, the permissible number of major blemishes and their positions shall be agreed with the purchaser.

Woven wire cloth may be covered with a film of oil as a result of the weaving process.

The wires may show traces of auxiliary materials used in the drawing process. Depending on the wire

material, there may be traces of corrosion.

The surface may show markings caused by the drawing and/or weaving process.

Explore the Versatility of Plain Weave and Twilled Weave

Plain Weave: Simplicity and Reliability

The plain weave mesh is known for its consistent opening sizes and high level of stability. It's a cost-effective solution for various filtration and screening needs, ensuring reliable performance in diverse environments.

Twilled Weave: Enhanced Strength and Durability

Ordering Information

📋 Essential Information

📝 Additional Information

Delivery & Packaging

Delivery Options

Delivery Options• Rolls or cut-to-size pieces

• Standard roll lengths: 25m or 30m

• ±10% tolerance on roll length

Packing

Packing• Discretion of the supplier unless specified

• Protected from damage and moisture

• Securely fastened to prevent shifting

Labelling

Labelling• Supplier information

• Dimensions and specifications

• Material type and batch number

• Handling instructions

Selvedge Options

Selvedge Options• Can be supplied with selvedge (edge binding)

• Can be supplied without selvedge

• Selvedge type specified in order

Ensuring Precision and Quality with ISO 9044 Standards

At Mutual Metal, we adhere strictly to ISO 9044 standards, ensuring our industrial woven wire cloth meets rigorous technical requirements. Our commitment guarantees superior quality and reliability in every product, providing optimal performance for diverse applications. We focus on delivering excellence through meticulous testing and adherence to global benchmarks.

Testing Methods

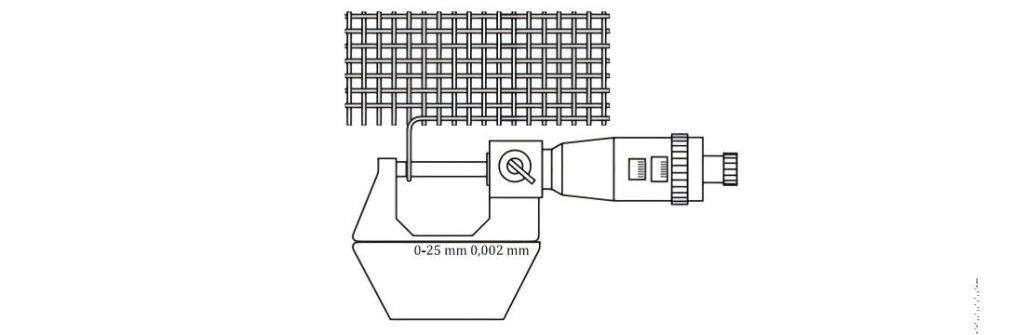

Wire Diameter

- by measuring wires which have been loosened from the woven wire cloth;

- by measuring the wires in the cloth, if there is sufficient space for the measuring instrument;

- by calculation from the mass per unit area;

- by an optical projection or scanning method.

method for measuring wire diameters

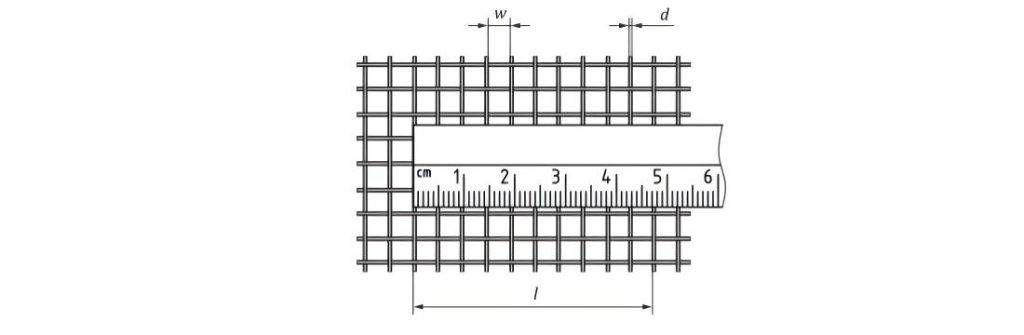

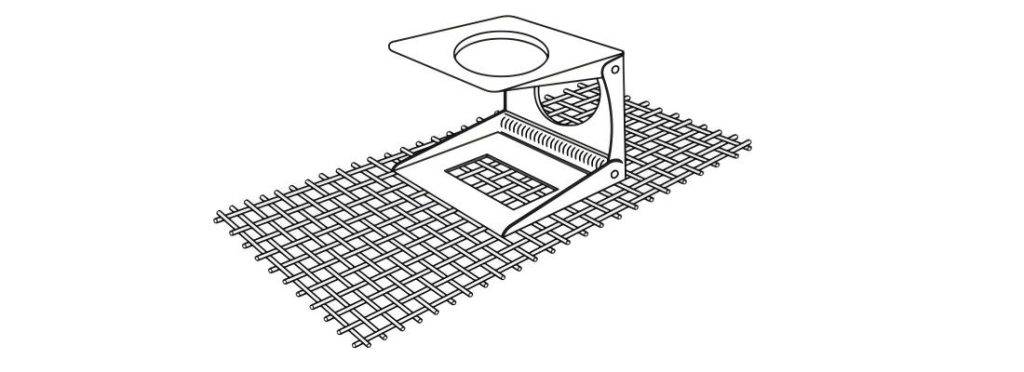

Aperture width

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Aperture widths greater than 4,0 mm

Aperture widths from 1 mm up to 4 mm

The test procedure shall be as left, but the span of 20 pitches shall be measured and the test result divided by 20, to give the average pitch.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Aperture width (Measuring row method)

In this simplified method, the number of pitches (p) in a given length (L) is determined. The given length is then divided by the number of pitches to give the average pitch. Subtraction of the wire diameter (d) from the