- Home

- Products

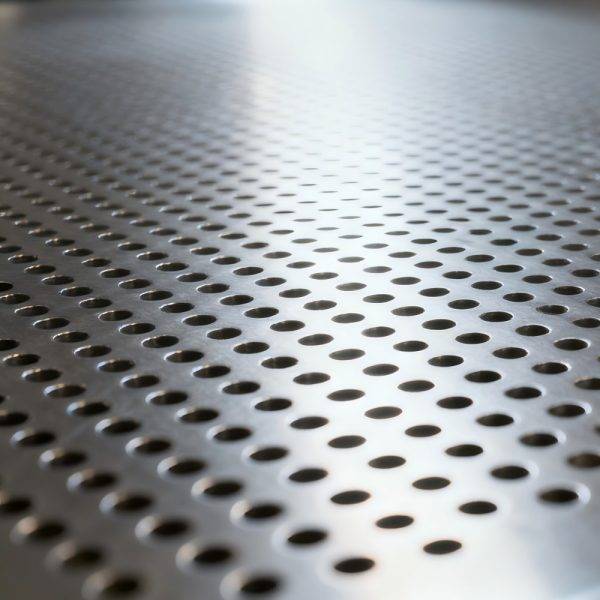

- Perforated Metal

- Round Hole

Round hole perforated metal offers exceptional versatility and precision. Ideal for a wide range of applications, from filtration and screening to architectural design and sound dampening, it combines functionality with aesthetic appeal. Trust Mutual Metal for quality and reliability.

Round hole perforated metal is the most popular perforated product. Standard hole sizes range from .020” to 1” diameter. For specialty applications, there are additional options for larger hole sizes.

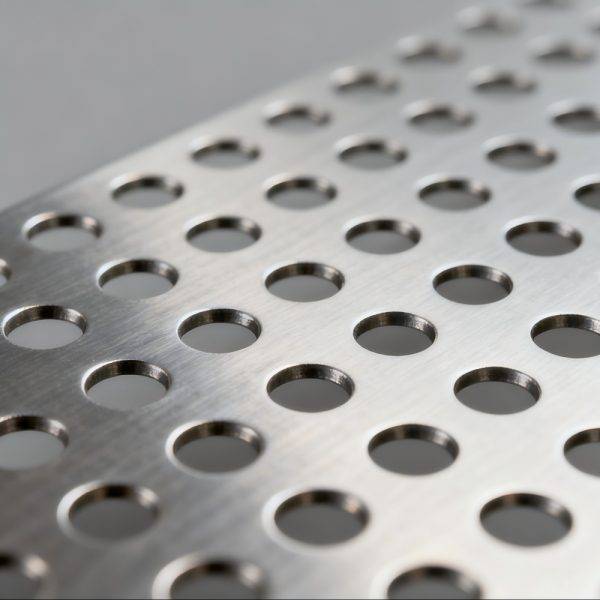

Materials in our inventory include steel, aluminum, stainless steel, and a variety of specialty alloys. Standard material thickness ranges from 26 gauge to 1/2” thick.

The versatile round hole patterns are ideal for applications including architectural accents, industrial screening products, and filtration solutions.

Stainless steel (AISI 304, AISI 304L, AISI 316L, AISI 310, AISI 321 – AISI 430 – AISI 904), carbon steel (FE360 – FE510), galvanized, high strength steel, polypropylene, polyethylene, pvc monel, inconel, hastelloy, aluminium (alloy 1050, alloy 5754), cupronickel, nickel, duplex, superduplex, brass, copper, titanium, etc.

From 0.4 mm to 20 mm.

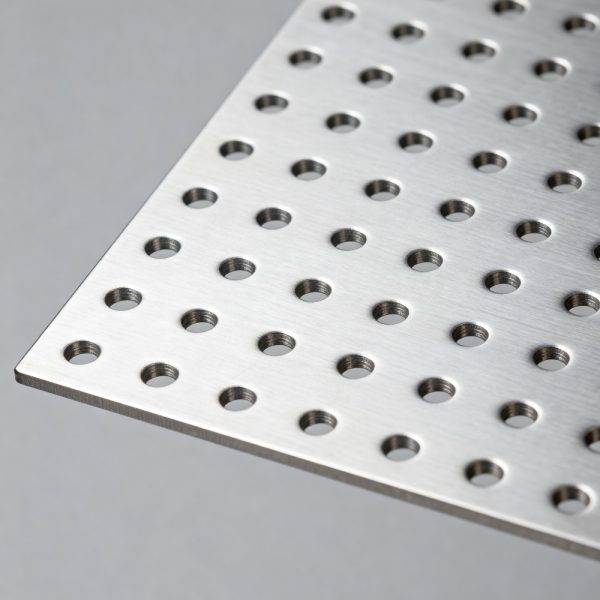

1000×2000 – 1250×2500 – 1500×3000 mm – custom-made sheet sizes – (edges and perforated areas on request)

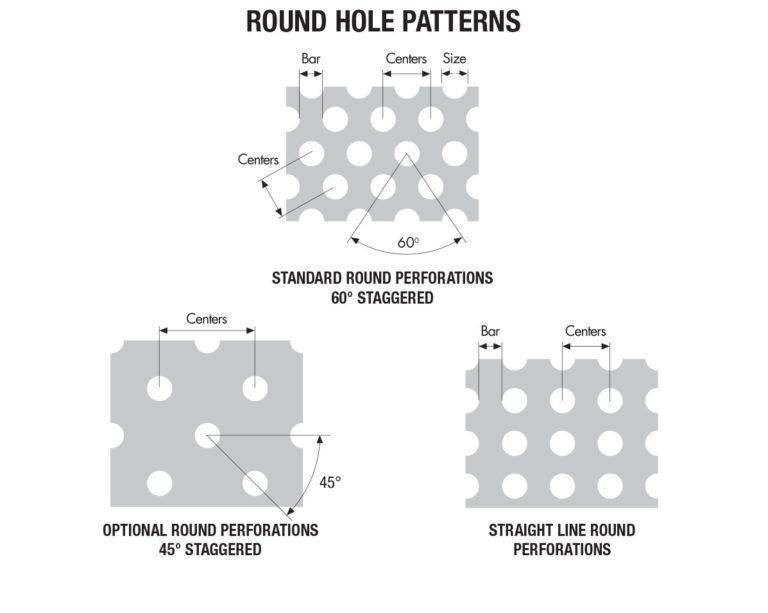

Round holes at 60° – 90° – 45°.

Round holes are the most in demand. The diameter of the holes goes from a minimum of 0.4 mm to a max 120 mm (other holes on request).

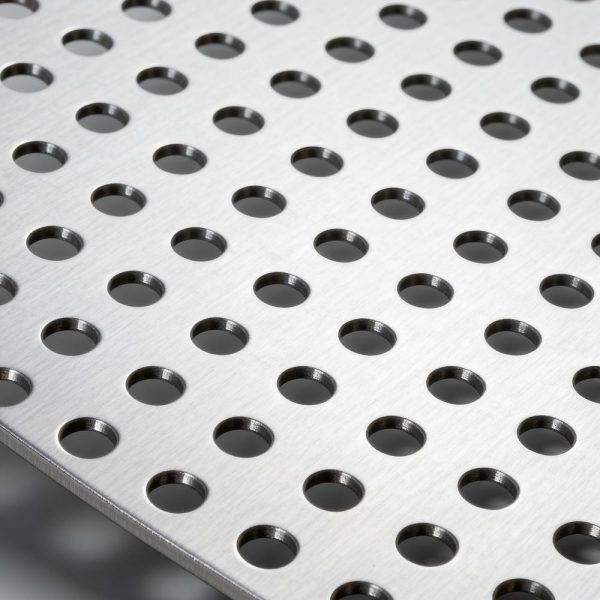

Round hole perforated materials are available in three unique patterns: 60° Staggered, 45° Staggered, and Straight Line. With varying amounts of open area, these hole patterns provide specifiers with flexibility in function as well as appearance.

If the products illustrated in this section do not address the specific needs of your application, please contact our sales team. We will gladly assist in the development of a custom perforated pattern tailored to your exact requirement.

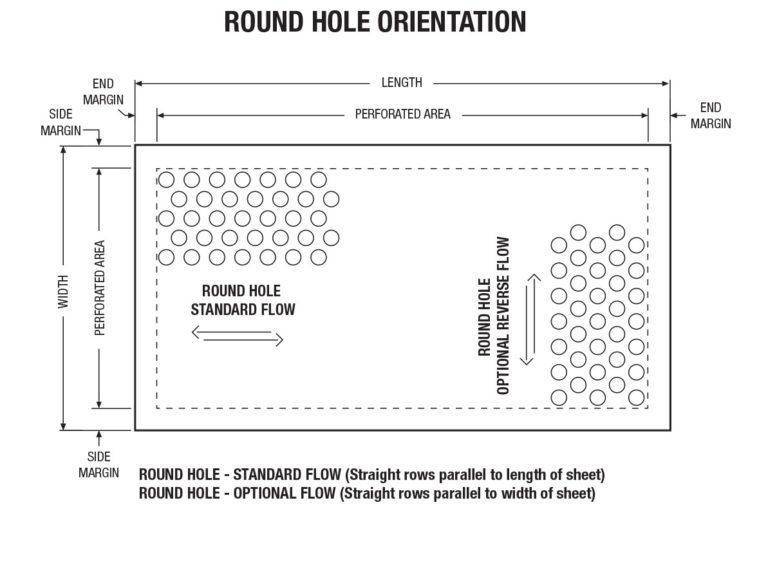

Our inventory is produced with the holes aligned in Standard Flow . This designates the straight rows of the holes are parallel to the length of the sheet.

Optionally, products may be special ordered Reverse Flow , where the straight rows of the holes are parallel to the width of the sheet.

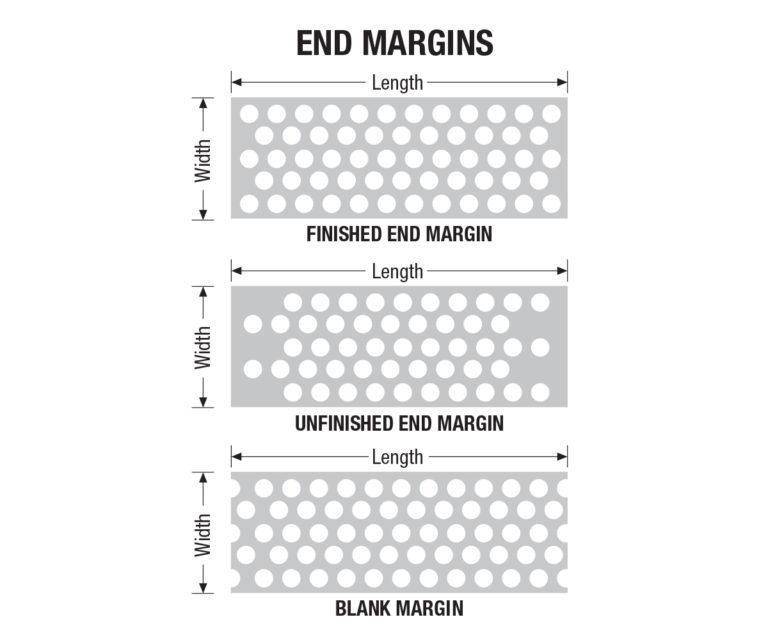

Finished End Margin: The round perforation pattern is uniform in appearance and complete at all edges of the sheet.

Unfinished End Margin: Round perforations are not solid in appearance at the edge of the sheet.

Blank Margin: Round perforations run completely to the width edges of the panel with some perforations remaining open at the sheet’s edge.

Explore our premium products, crafted with precision and quality for diverse industrial applications.