sales@mutualmetal.com

+86 180 3366 6533

- Home

- Products

- Woven Wire Mesh

- Micronic Mesh

Micronic Mesh, also known as micron mesh, is used mainly for filtering liquids because it has very tiny openings, measured in microns. It is often stronger and more durable than square weave wire mesh. There are two main types of weaves: Dutch and Twilled Dutch, with several common variations. The most important factor in choosing the right mesh is the size of particles it needs to filter out, known as micron retention size. Gerard Daniel manufactures micron wire mesh in common weaves ranging from 15 to 200 microns, with 100 microns being the most common.

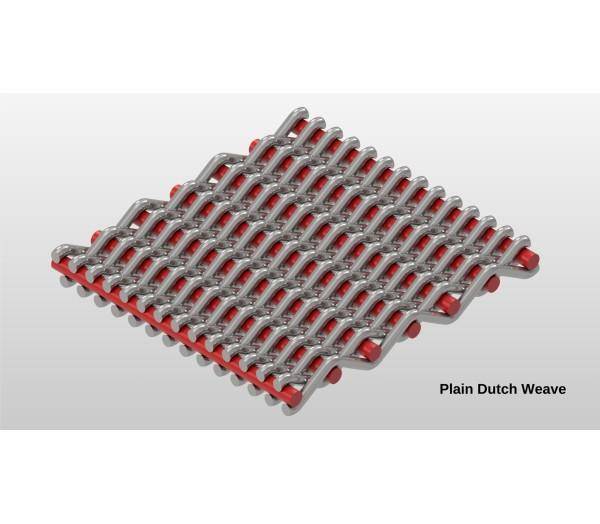

Dutch weave features interwoven wire, with thicker warp wires closely arranged to form a stable zero-mesh structure. This design offers excellent filtration and easy cleaning of deposits and dirt.

Twilled Dutch weave (TDW) has closely spaced shute wires, double the amount found in plain Dutch weave. This creates small openings from three shute wires crossing, forming channels open on two sides for precise filtration. Open Twill Dutch Weave Wire Mesh uses fewer shute wires for adjustable filtration rates.

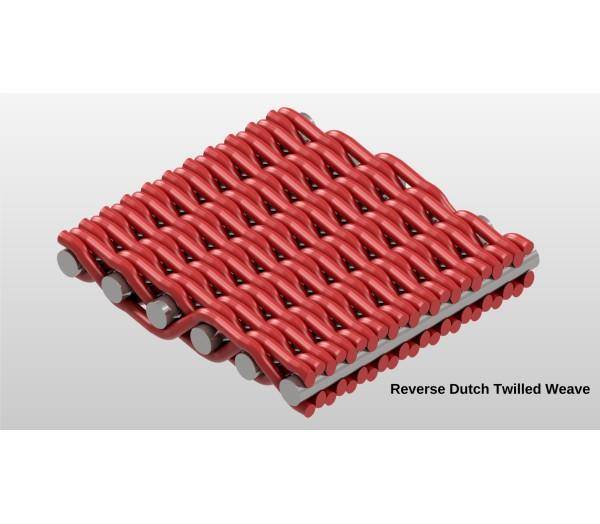

A type of reverse dutch weave is the reverse dutch twilled weave, featuring thin warp wires like the standard version, but with shute wires arranged in a twill pattern. This design offers strength, making it suitable for high mechanical stress situations.

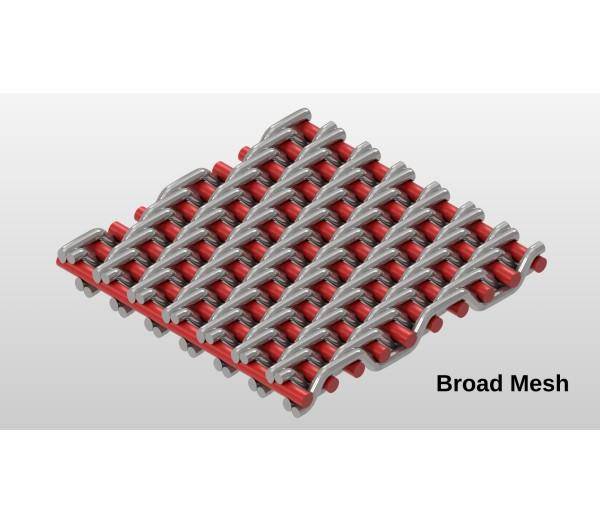

To improve the filtration ability of the broad weave mesh cloth, the threads used in the weave are placed loosely rather than tightly. This results in lower accuracy compared to a traditional twilled weave, but it still meets the needs of most applications. The surface of the BMT cloth is smooth on both sides, making it easy to clean.

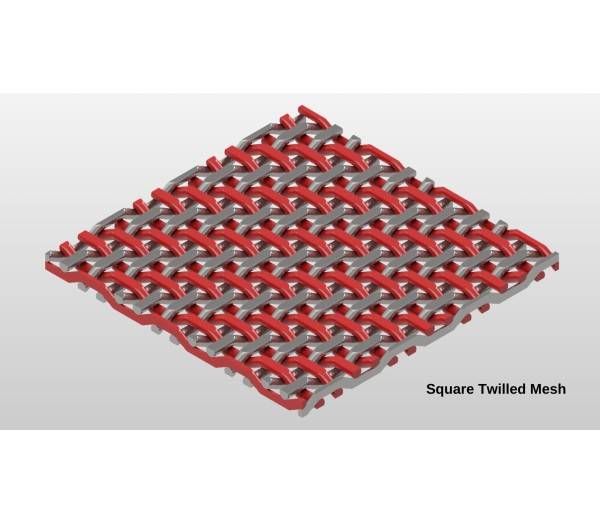

The cloth features equal mesh counts in both directions, similar to plain square mesh. In a square twilled weave, each warp and shute wire passes over two and under the next pair of wires, resulting in less deformation and stress on the warp wires compared to a plain weave. This design's strength makes it ideal for high mechanical stress applications.