- Home

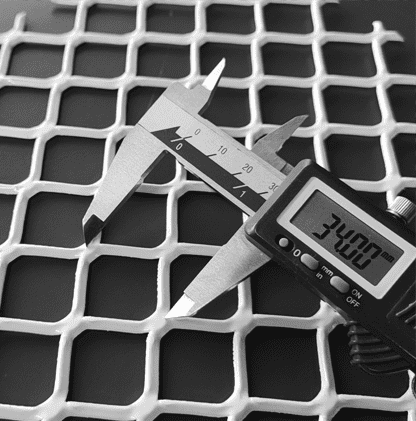

- quality control

ISO 14001:2015

To ensure that products remain undamaged during transportation, we use waterproof, moisture-resistant, and shatterproof materials for packaging, considering the chemical and physical properties of the products. Additionally, we can provide customized packaging tailored to the specific requirements of each customer to meet their individual needs.