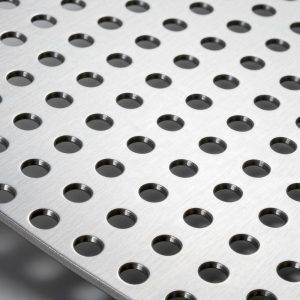

Perforated metal mesh is widely used across architecture, industrial machinery, acoustic panels, filtration systems, and decorative applications—thanks to its high strength, aesthetic appeal, excellent airflow and light transmission, and highly customizable hole patterns. Yet, many are unaware of the sophisticated manufacturing process behind this seemingly simple metal product.

In this article, we’ll walk you through the complete production workflow of perforated metal mesh, revealing how a standard metal sheet transforms into a precise, functional, and visually striking finished product.

1. Raw Material Preparation

The process begins with selecting the appropriate base material, typically supplied as coils or flat sheets. Common materials include:

- Stainless Steel (e.g., grades 304, 316): Offers excellent corrosion resistance and strength—ideal for food, medical, and chemical environments

- Carbon Steel: Cost-effective and strong; often used in construction or general industrial applications, frequently coated with paint or galvanized

- Aluminum/Aluminum Alloys: Lightweight, corrosion-resistant, and easy to form—popular in architectural cladding, aerospace, and heat dissipation

- Copper, Brass, or Galvanized Steel: Chosen for decorative purposes or specialized conductivity needs

All incoming materials undergo rigorous quality inspection for thickness tolerance, surface flatness, and defects such as scratches or oxidation to ensure consistent perforation quality and final appearance.

2. Uncoiling and Leveling (for Coil Stock)

When using coiled metal, the first step involves feeding the material through an uncoiler, followed by a leveler (or roller leveller). This removes internal stresses and eliminates waviness or camber in the sheet.

Proper leveling is critical—any residual deformation can lead to misaligned holes, inconsistent hole shapes, or even damage to the punching dies during subsequent operations.

3. CNC Punching (The Core Process)

Punching is the heart of perforated mesh production, determining key characteristics like hole shape, diameter, pitch, and pattern layout. Modern facilities rely on CNC turret punch presses or servo-driven punching machines for high precision and flexibility.

1) Die Selection and Setup

Based on the design specifications—round, square, slotted, hexagonal, or custom-shaped holes—the appropriate punch and die set is installed. High-quality tooling ensures clean, burr-free edges.

2) Programming and Positioning

Design files (typically CAD) are converted into machine code via CAM software. The CNC system then controls the precise movement of the sheet under the punch head, enabling complex layouts such as staggered, honeycomb, or gradient-density patterns.

3) Punching Operation

Under controlled tonnage and speed, the punch shears through the metal, and the slug (waste material) drops into a collection chute. Advanced machines achieve micron-level positioning accuracy and high throughput without compromising quality.

Did You Know? Micro-perforation (holes under 1 mm) demands ultra-stable machinery and specialized tooling, sometimes supplemented by laser drilling for extreme precision.

4. Deburring and Surface Finishing

After punching, sharp edges or burrs around holes can pose safety risks and interfere with downstream processes. Therefore, parts typically undergo:

- Mechanical Deburring: Using brush rollers, abrasive belts, or vibratory tumbling

- Chemical or Electrolytic Deburring: For high-precision or sensitive applications

Next, surface treatments are applied based on the end use:

- Powder Coating or PVDF Painting: Enhances weather resistance and visual appeal—common in architectural panels

- Galvanizing or Electroplating: Boosts corrosion protection for carbon steel

- Anodizing (for aluminum): Improves surface hardness and enables color customization

- Brushed or Mirror Polishing: Used in premium acoustic grilles or decorative elements

5. Cutting and Forming

Once perforated, large sheets are cut to final dimensions using methods like:

- Shearing

- Laser Cutting (for intricate contours)

- Plasma or Waterjet Cutting (for thicker materials)

If the design requires 3D geometry—such as curved facades, cylindrical filters, or bent safety guards—the sheets are shaped using press brakes, roll formers, or hydraulic forming presses. Special care is taken during forming to avoid distorting the perforated areas, as the material’s rigidity is reduced after punching.

6. Quality Inspection and Packaging

Every batch undergoes thorough quality control:

- Hole diameter and pitch verification (via optical comparators or vision systems)

- Dimensional accuracy and flatness checks

- Surface inspection for scratches, coating defects, or residual burrs

- Salt spray testing (for outdoor applications to validate corrosion resistance)

Approved products are cleaned, protected with surface film (to prevent scratches), and packaged securely—either palletized, crated, or rolled—ensuring safe transit to the customer.

7. Application Insights: Why Process Dictates Performance

- Architectural Cladding: Requires uniform hole patterns and flatness to achieve consistent light/shadow effects

- Industrial Sieves: Hole precision directly impacts screening efficiency; smooth edges prevent material hang-up

- Speaker Grilles: Open area ratio and hole geometry affect acoustic transparency; surface finish defines aesthetics

- Machine Guards: Structural integrity and edge safety are non-negotiable

Conclusion

While perforated metal mesh may appear straightforward—just “holes in metal”—its production is a sophisticated integration of material science, precision mechanics, automation, and surface engineering. Each step in the process is calibrated to balance functionality, durability, and design.

So the next time you admire a sleek perforated facade or rely on a robust industrial screen, remember: behind that elegant simplicity lies a highly refined, meticulously controlled manufacturing journey.

Pro Tip: When ordering custom perforated mesh, always provide detailed drawings specifying hole pattern, material grade, surface finish, and intended environment. This enables manufacturers to optimize the production process—delivering better performance, longer life, and greater value.