Material

Spacing

Woven and Welded Wire Cloth are identified and manufactured based upon their mesh sizes (wire spacings). These mesh sizes are expressed in either center-to-center wire spacings, clear opening between the wires, or mesh count.

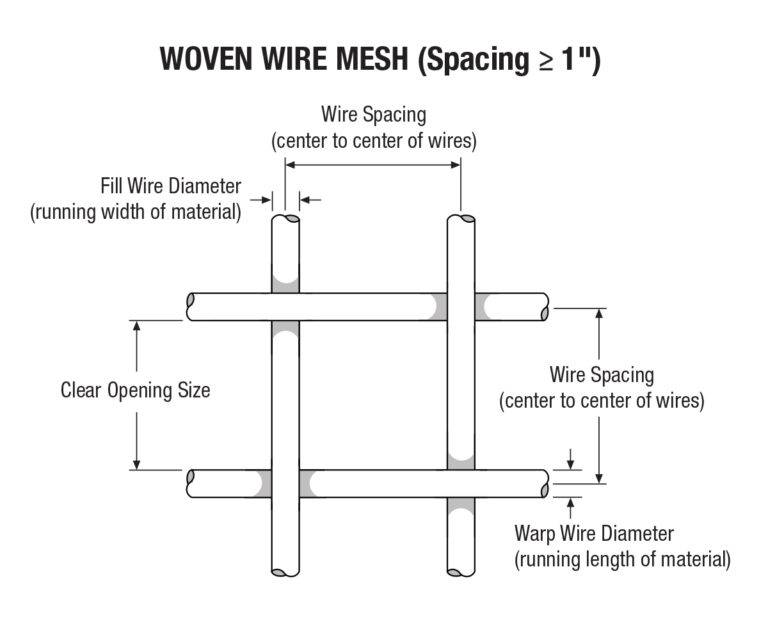

Woven Wire Mesh

Woven products are specified as either Mesh, meaning center-to-center of wires, or Clear Opening which indicates the opening between the wires.

Example 1 – Mesh: 1” square mesh woven wire produced with .135 wire will be manufactured with the wires spaced 1” on center, resulting in a .865 clear opening.

Example 2 – Clear Opening: 2” clear square opening woven wire mesh produced with .250 wire will be manufactured with the wires spaced 2-1/4” on center, resulting in a 2” clear opening.

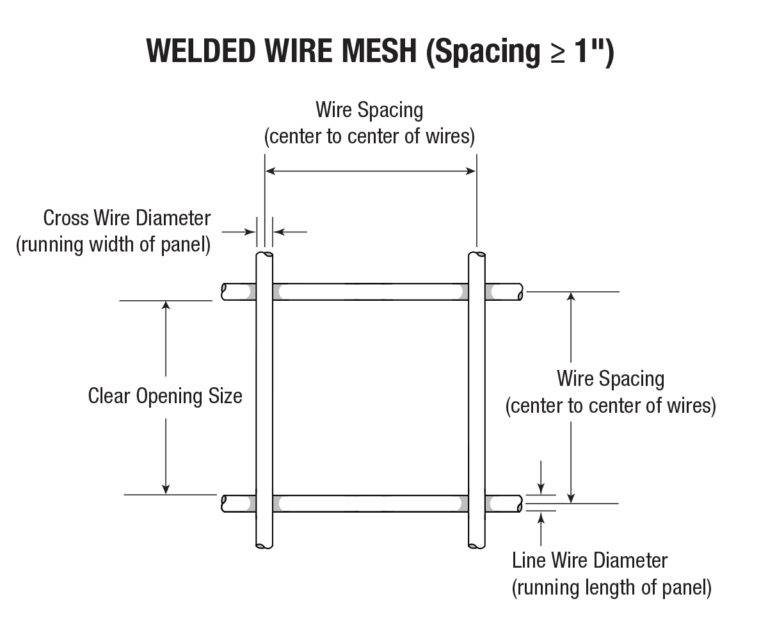

Welded Wire Mesh

Welded products, with openings equal to or exceeding 1”, are specified based on the center-to-center spacing of the wires.

Example: 2” square welded wire mesh produced with .250 wire will be manufactured with the wires spaced 2” on center, resulting in a 1-3/4” clear opening.

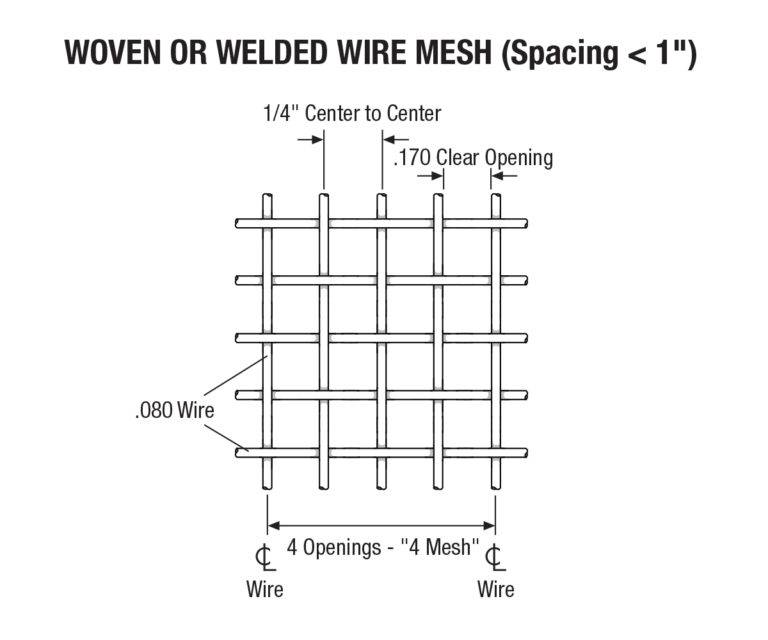

Woven or Welded Wire Cloth – meshes less than 1” on center

Wire Cloth and Hardware Cloth, with mesh sizes less than one inch can be specified three ways. For the material illustrated, which is a Wire Cloth with .080 wires spaced at 1/4″ on center, the product may be specified in any of the following manners:

- Mesh Count: 4 Mesh, .080 wire

- Center-to-Center Spacing: 1/4″ mesh, center-to-center, .080 wire

- Opening Size: .170 clear opening, .080 wire