Discover the Strength of

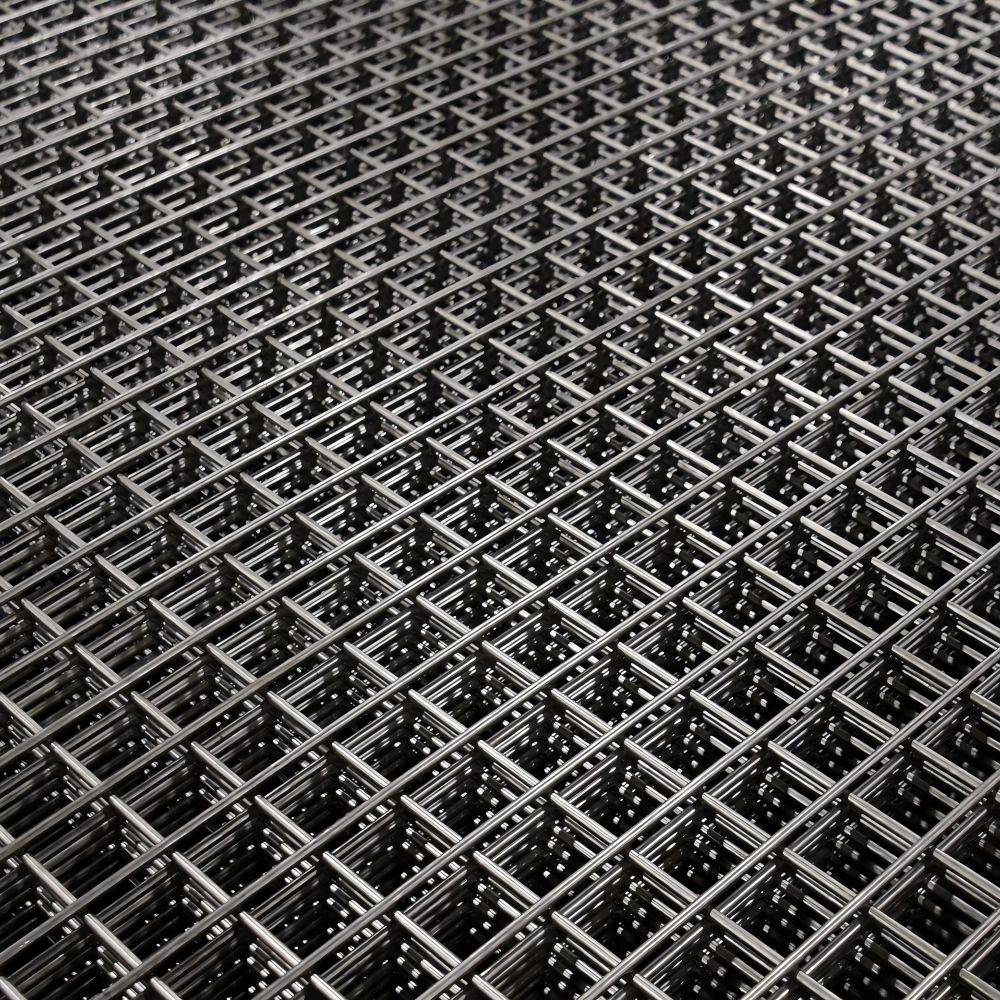

Welded wire mesh is a versatile and cost-effective solution for a wide range of applications. We provide high-quality welded wire mesh known for its strength, durability, and precise dimensions. It is ideal for construction, agriculture, and industrial uses.

Economical and durable, welded wire mesh is manufactured on state-of-the-art, automated, grid welding equipment. Line and cross wires lay flat at each intersection and are resistance welded for maximum cross-sectional strength. Ideal for industrial use as well as architectural applications.

Materials Available: plain steel, pre-galvanized, stainless steel

Wire diameters: .035” to .375”

Square or rectangular mesh

Stock panels or rolls

Specialty products available on request

It is Rigid and strong because every intersecting joint of two wires is resistance welded. Flat panels have many uses as raveling of wires and wracking of panels are nonexistent. Flat panels of welded wire mesh can be made with square or slotted openings.

Some uses for welded wire mesh panels are:

- Re-enforcement for plaster of concrete

- Zoo animal cages

- Cattle confinement pens

- Wall, ceiling and floor module display systems

- Stairway and boat railing filler panels for decoration and safety

- Over head conveyor guards

Industrial needs drive diverse wire mesh materials with varying properties. Selection depends on usage, strength, abrasion, corrosion, and heat resistance.

Common materials described:

Plain Carbon Steel: Low-carbon steel offers tensile strength and impact resistance, with coatings like galvanizing or epoxy for better corrosion resistance. High-carbon steel suits abrasive conditions, while oil-tempered wire provides maximum strength and abrasion resistance.

Stainless Steels: Chromium addition provides corrosion resistance; types include 304, 316, and higher alloys for salt, acid, or heat tolerance. Nonmagnetic alloys, like 304L, excel in high temperatures. Magnetic Alloys: Types like 410 and 430 withstand heat and corrosion, with specific high-temperature tolerances.

Copper/alloys: Copper resists corrosion but has low strength; brass and bronze improve abrasion and corrosion resistance. Bronze-phosphor is tough but vulnerable to strong acids.

Aluminum alloys: Light, corrosion-resistant, and ideal for marine environments.

Nickel/alloys: Pure Nickel shields against corrosion; Monel and Hastelloy offer strength and oxidation resistance, often replaced by stainless steel in modern uses.

MATERIAL – Indicate material such as plain carbon steel, stainless steel or other alloy.

WIRE DIAMETER OR GAUGE – In decimal, thousands of one inch, or gauge.

WIRE SPACING – Specify square, rectangular or specialty configuration. Wire spacing center-to-center, clear opening, or mesh count.

SIZES – Indicate sheet or roll width and length, or width and length of cut-to-size pieces.