Editorial by Industrial Quick Search

Discover the Many Benefits and Uses

Fundamentals of Wire Mesh

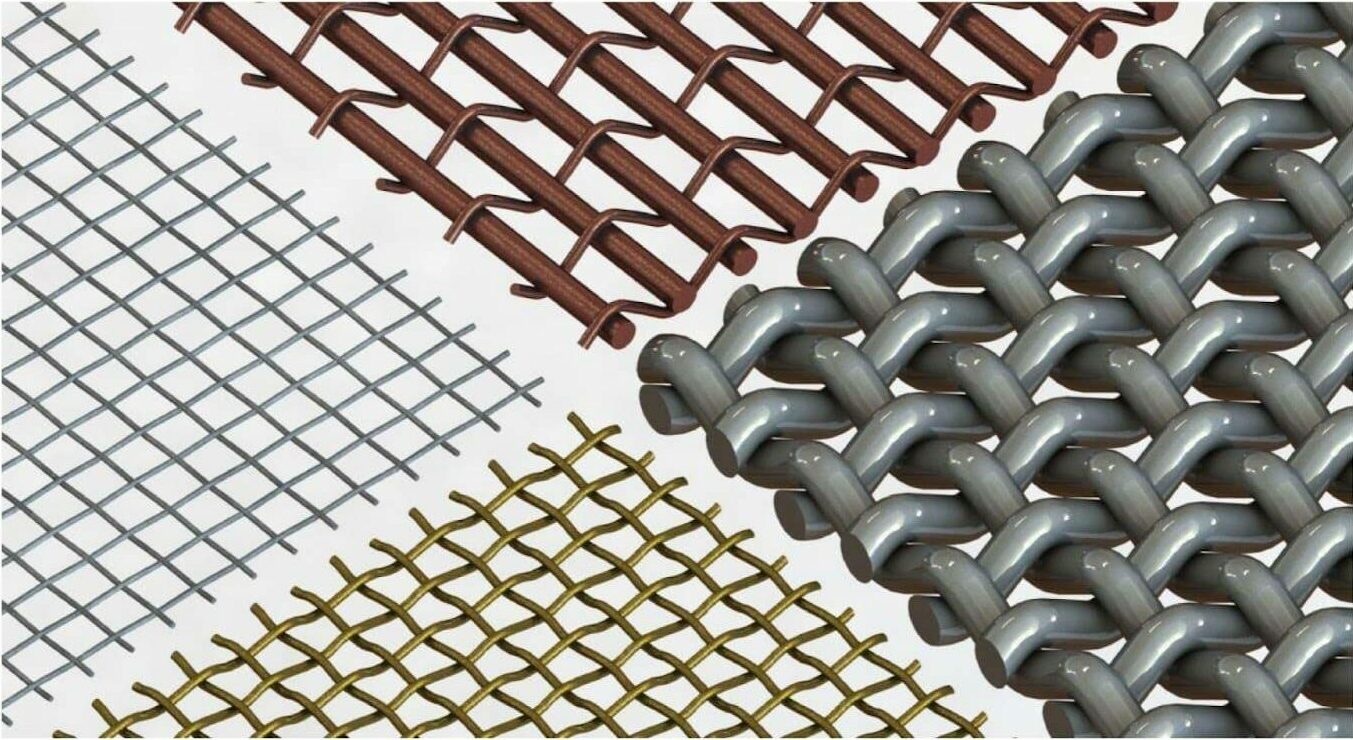

Wire mesh, often known as wire fabric, wire cloth, or hardware mesh, is crafted by interlacing, weaving, or welding wires of variable thicknesses into uniformly spaced rows and intersecting columns. Crafted on industrial looms, this method produces square or rectangular openings between wires. Alternatively, welded wire mesh is crafted by electrically welding intersecting longitudinal wires.

There is an almost endless array of shapes, sizes, and configurations of wire mesh crafted from a variety of robust materials. These mesh configurations primarily function to separate, screen, structure, and shield various applications and processes. Wire types include galvanized steel , stainless steel, aluminum, steel, and copper alloys. Factors such as the intended use, required tensile strength, durability, lifespan, and necessary flexibility help in determining the ideal wire type and style.

Manufacturing Wire Mesh

The production of wire mesh involves weaving or welding. Weaving is akin to textile weaving on a loom, while welding joins wires at crossing points. Automated, pre-configured machinery facilitates both processes.

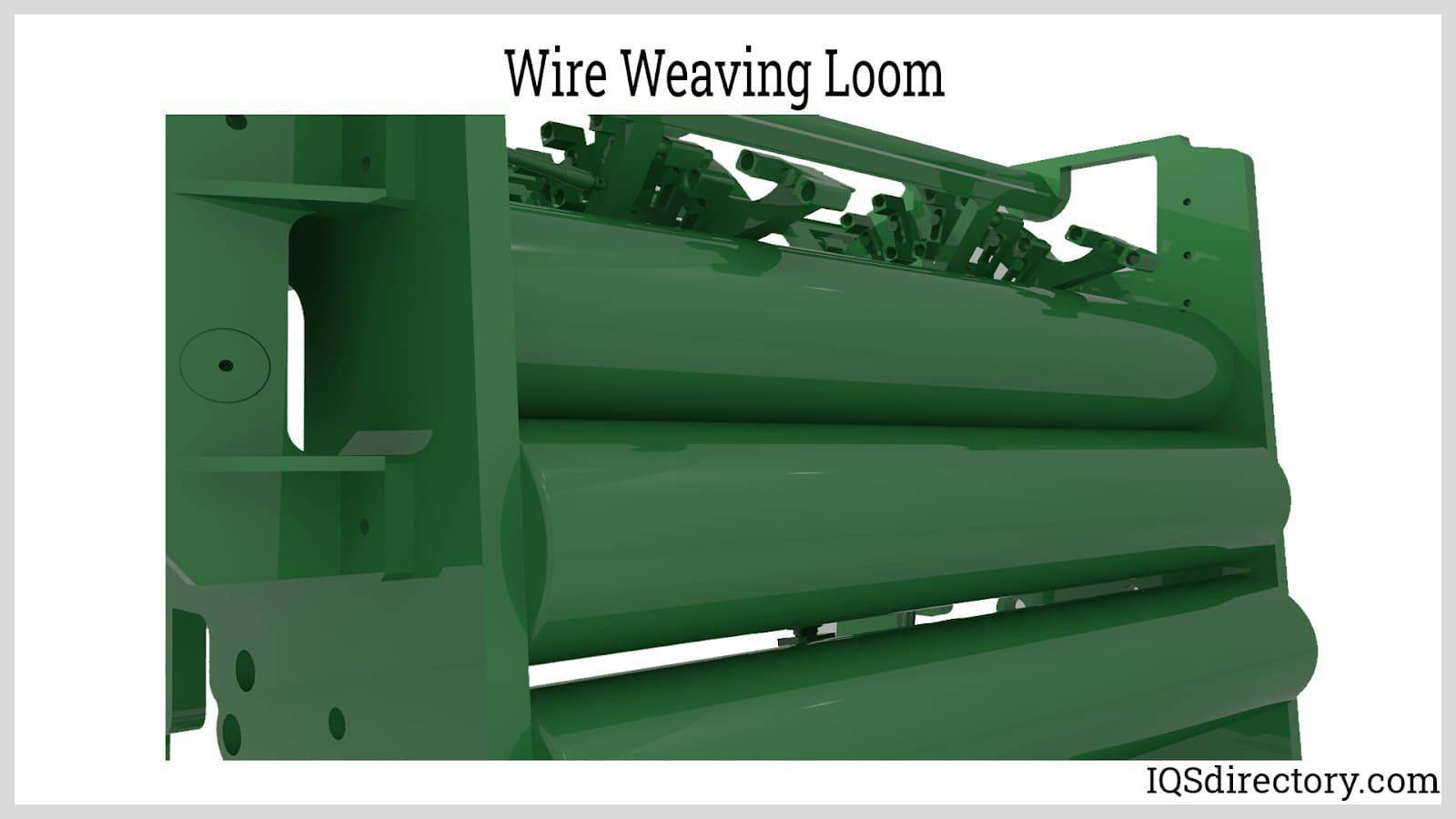

The Art of Wire Weaving

The demand for woven wire cloth surged in the late 17th century due to its use in the mining and pulp industries, prompting the development of wire weaving looms. Over time, wire mesh has evolved beyond its original purposes to be used in architecture, plastic extrusion , and filtration processes, as well as aggregate screening. This evolution has sparked the growth of the industrial wire weaving sector.

Once the loom is set up and warp beam loaded, weaving becomes an automated cycle. As the loom operates, the warp beam unwinds evenly while the take-up mechanism rolls up the finished fabric in sync. This coordination maintains appropriate tension, crucial for high-quality fabric production.

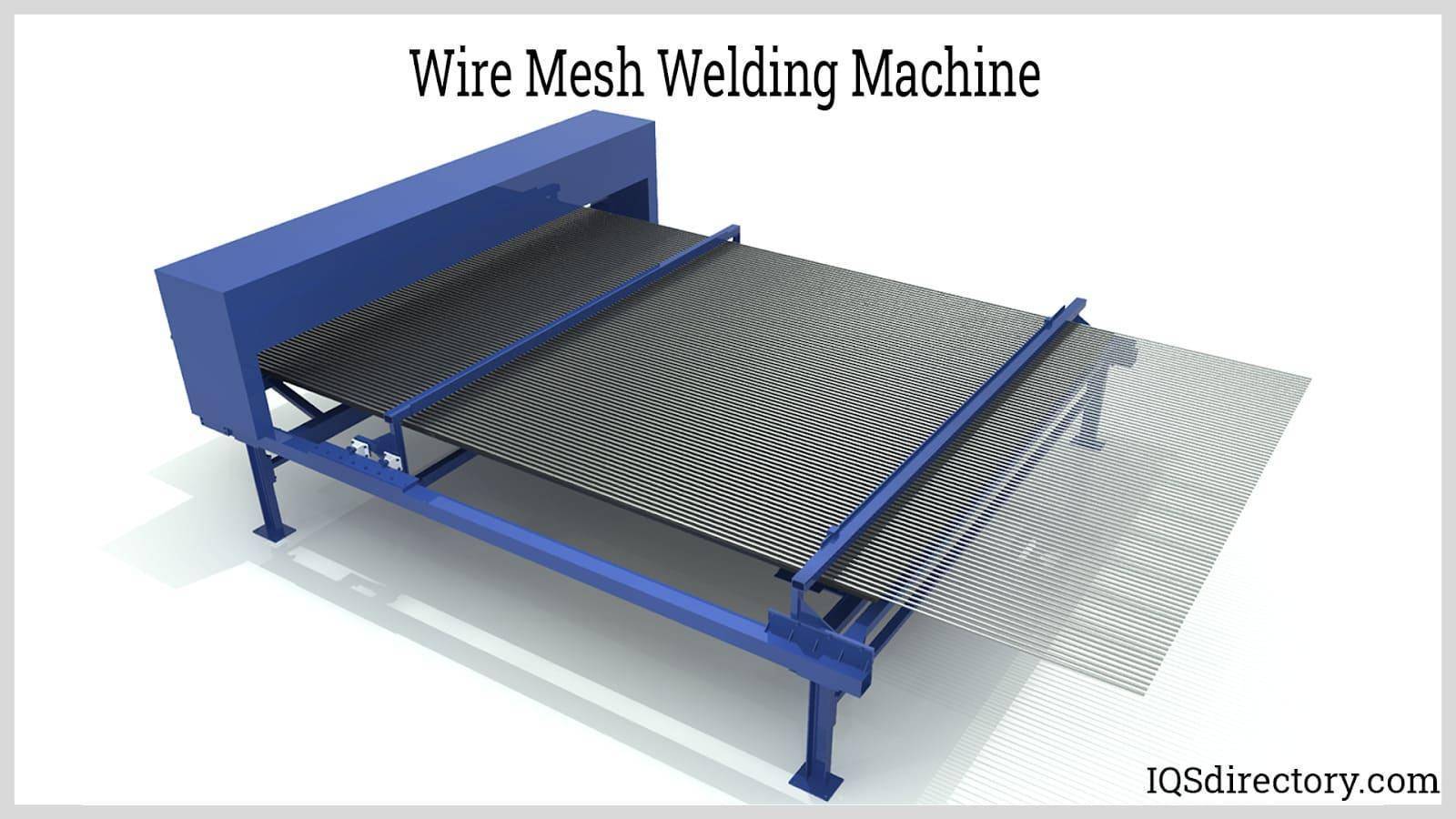

Welded Wire Mesh

Wire mesh welding involves a semi-automatic process where wire intersections are fused. Specialized welding machines apply uniform welds at each intersecting point using techniques like resistance welding, TIG welding, plasma welding, and soldering.

Often consisting of thicker wires for enhanced robustness and strength, welded mesh is usually more durable than woven mesh. Its welding process imparts additional rigidity, making it perfect for fencing, cages, and reinforcement applications in concrete.

Different Varieties of Wire Mesh

Wire mesh types are classified by fabrication methods, characteristics, functionalities, and weave designs, tailored for specific strength, weight, and finishing needs. Critical selection factors include metal type, mesh pattern, and finish, with metal choice being particularly essential.

Welded Wire Mesh

This mesh, formed by welding wires into square grids, is a strong choice for secure fencing, storage shelves, animal enclosures, room partitions, and pest traps.

Attributes of welded wire mesh include:

Stainless steel welded wire mesh inherits the corrosion resistance and sturdiness of its material, ensuring sustained performance.

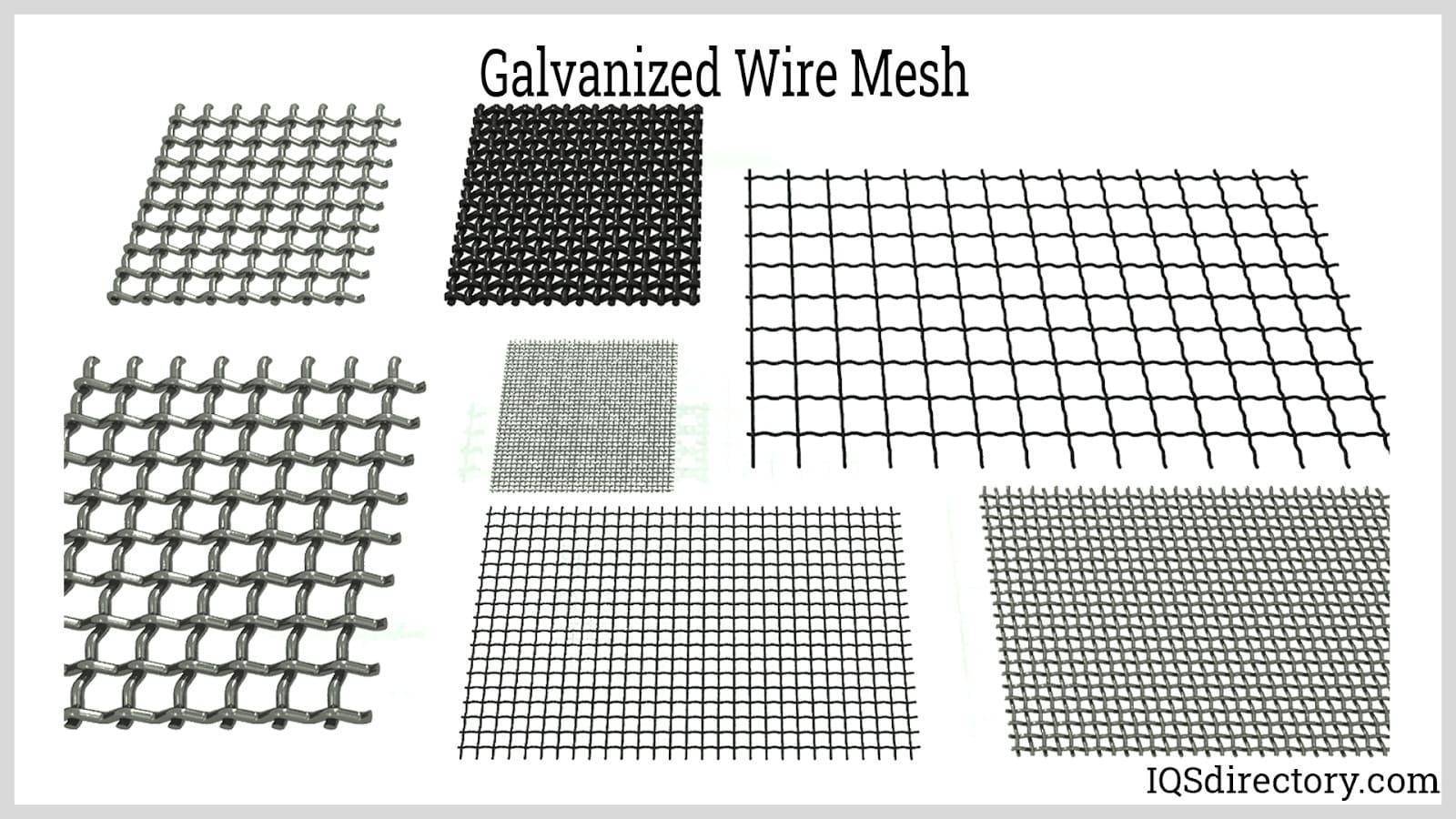

Galvanized Wire Mesh

Crafted from standard or carbon steel wire, galvanized wire mesh features a protective zinc coating applied during galvanization. This layer serves as a shield against rust and corrosion. Mesh made with galvanized wires or zinc-coated plain steel after weaving offers variable pricing, with post-galvanization yielding superior quality.

Galvanized wire mesh meets various needs, such as fencing for agriculture and gardening, greenhouses, architectural purposes, construction, protective barriers, window guards, and infill panels. Its affordability enhances its popularity among wire mesh types.

Vinyl-Coated Wire Mesh

Applying a vinyl coating to either woven or welded wire mesh forms a resilient protective layer that remains stable over broad temperature ranges, unaffected by sunlight, and resists damage. Vinyl coatings enhance visual appeal while bolstering durability, resisting rust and corrosion, and shielding against moisture and external elements by encasing the wires for lasting performance.

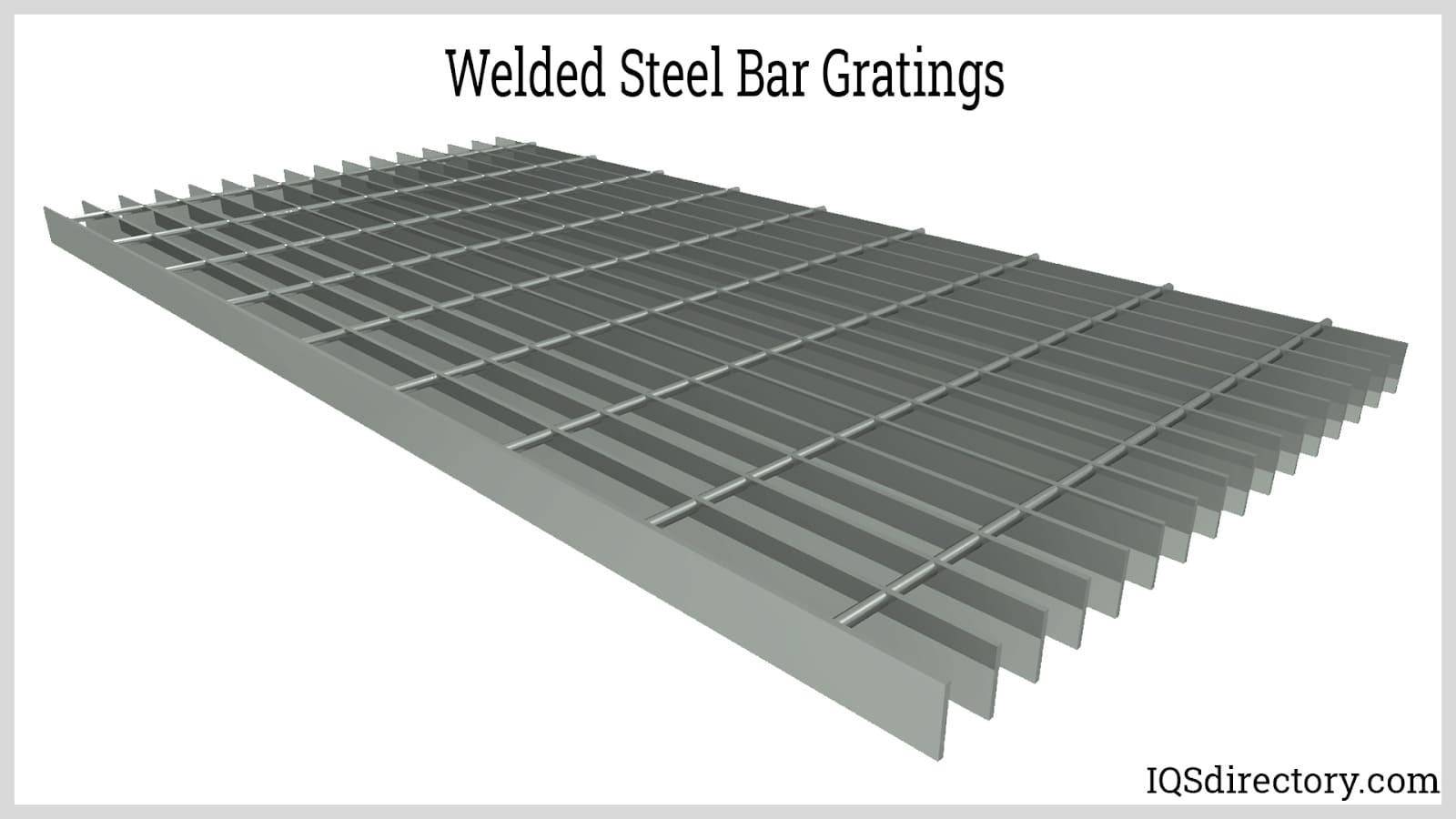

Welded Steel Bar Gratings

Welded steel bar gratings undergo forge welding at high temperatures, bonding vertical and horizontal bars for enduring strength and stability. Made from carbon or stainless steel, these gratings excel in robustness and rigidity.

Engineered for heavy-duty use, they are found in ramps, bridge decking, ventilation grilles, sidewalks, landings, and industrial floors. Panels vary in widths from two to three feet, lengths of two feet, with bar depths from 1” to 6” and thicknesses between 0.25” to 0.50”.

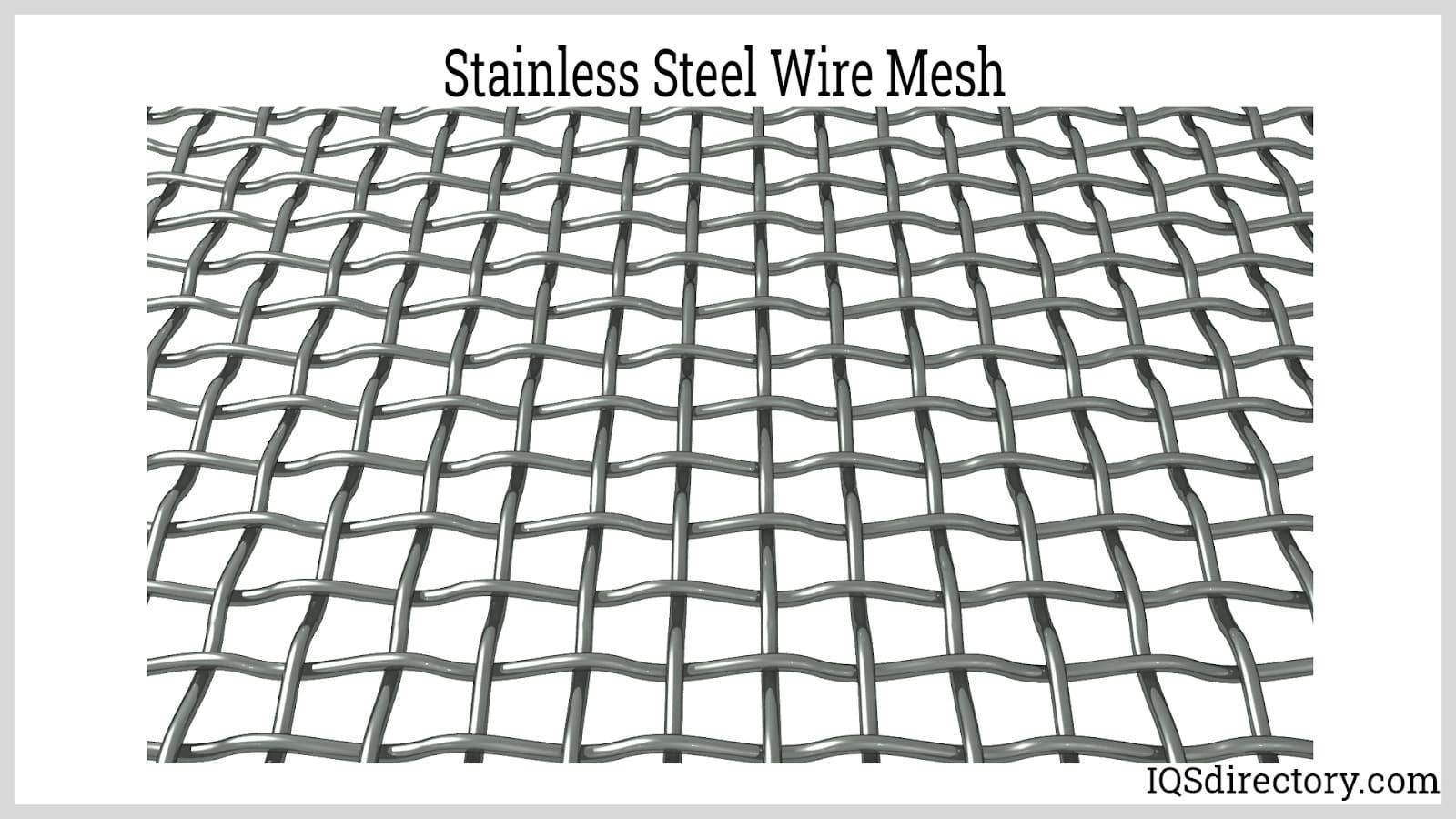

Stainless Steel Wire Mesh

Known for high-quality attributes, stainless steel mesh leverages its metal properties for outstanding performance. Where traditional steel is prone to rust, added chromium in stainless steel offers protective resistance to oxidation, elevating its suitability for outdoor applications.

Welded or woven, stainless steel mesh is favored for its reliability, immunity to corrosion, and suitability across diverse applications, especially for external and marine settings due to its resistance to climate challenges.

Common stainless steel grades include 304, 304L, 316, 316L, 321, 347, and 430, with wire diameters from 0.0085 inch (0.216 mm) to 0.307 inch (7.8 mm). Mesh openings, key in design, define usage, with those less than 0.25 inch (6.35 mm) termed wire cloth.

Grade 316 stainless steel, an ideal marine alloy, withstands oxidation, acids, and salt exposure excellently, available in fine to coarse varieties. Grade 304, though less corrosion-resistant than 316, is significantly workable and cost-efficient.

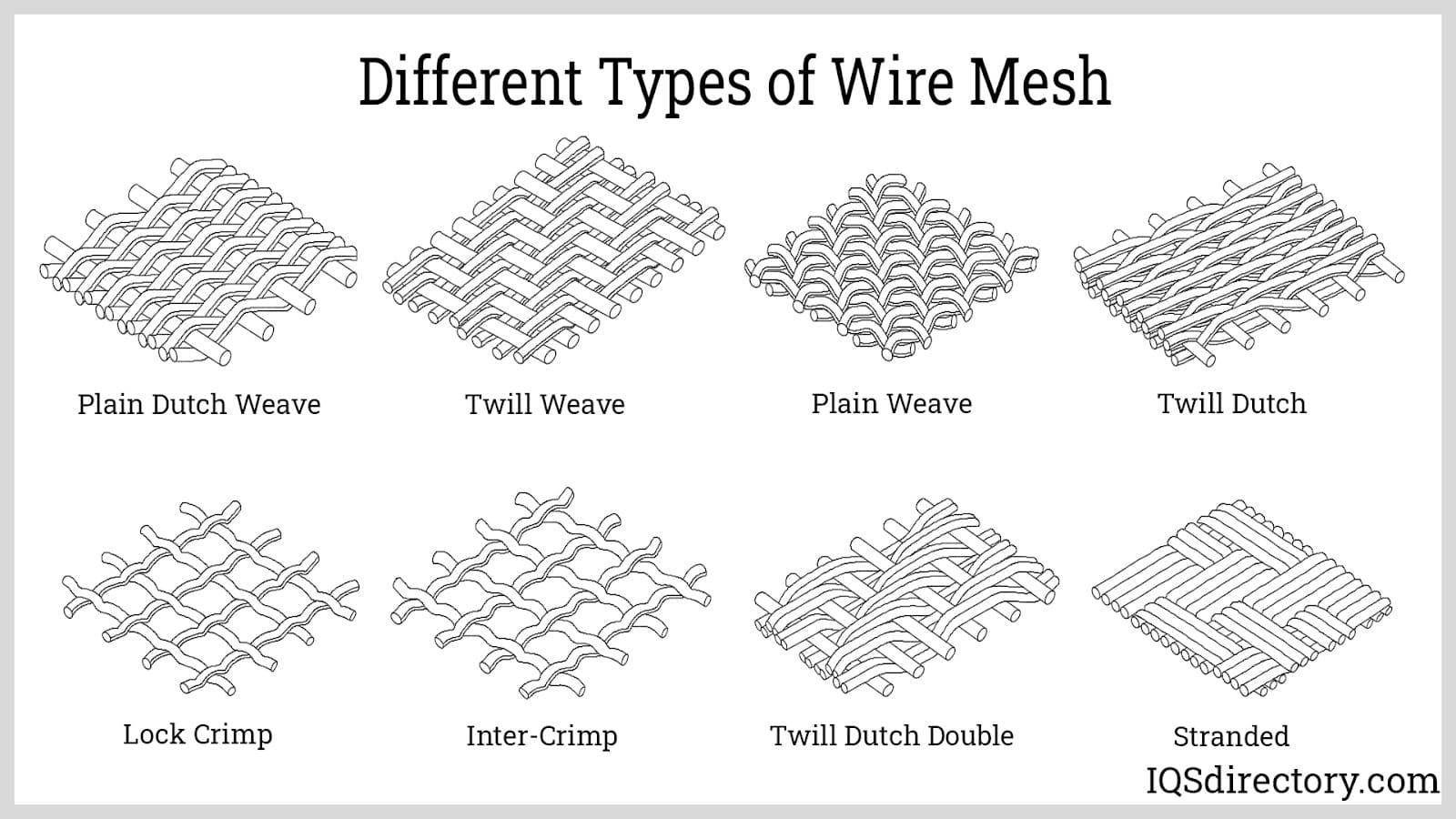

Wire Mesh Patterns

Wire mesh patterns determine its usage suitability across applications. There’s a range of standard and customized patterns. A defining characteristic is whether the wire is crimped, involving mechanical shaping of weft or warp wires to enhance functionality and appearance.

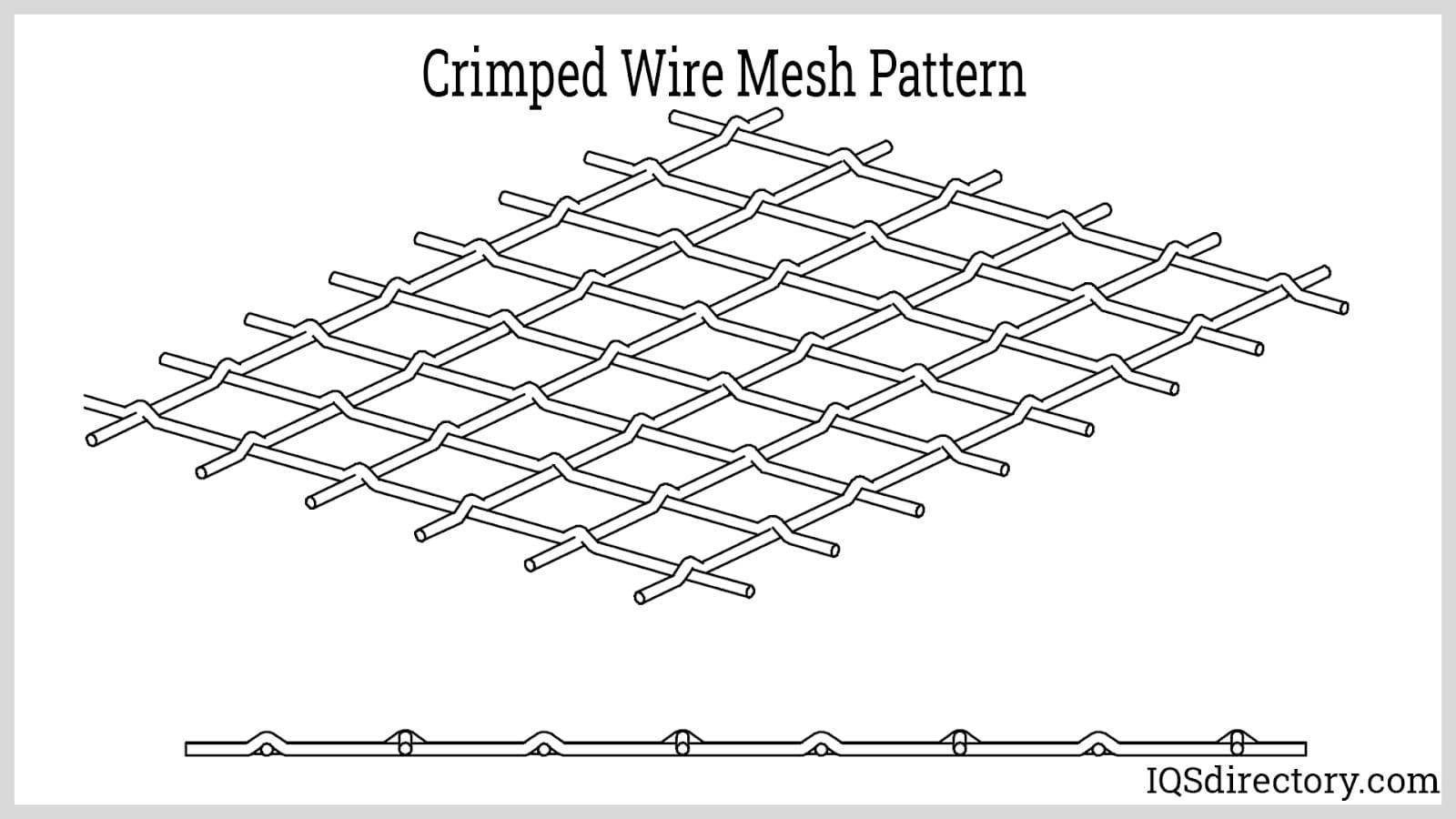

Crimped Wire Mesh

With either square or rectangular weaves, crimped wire mesh is made by a crimping mesh machine. The crimping process compresses wire so weft overlaps warp wires, creating an interlocking effect.

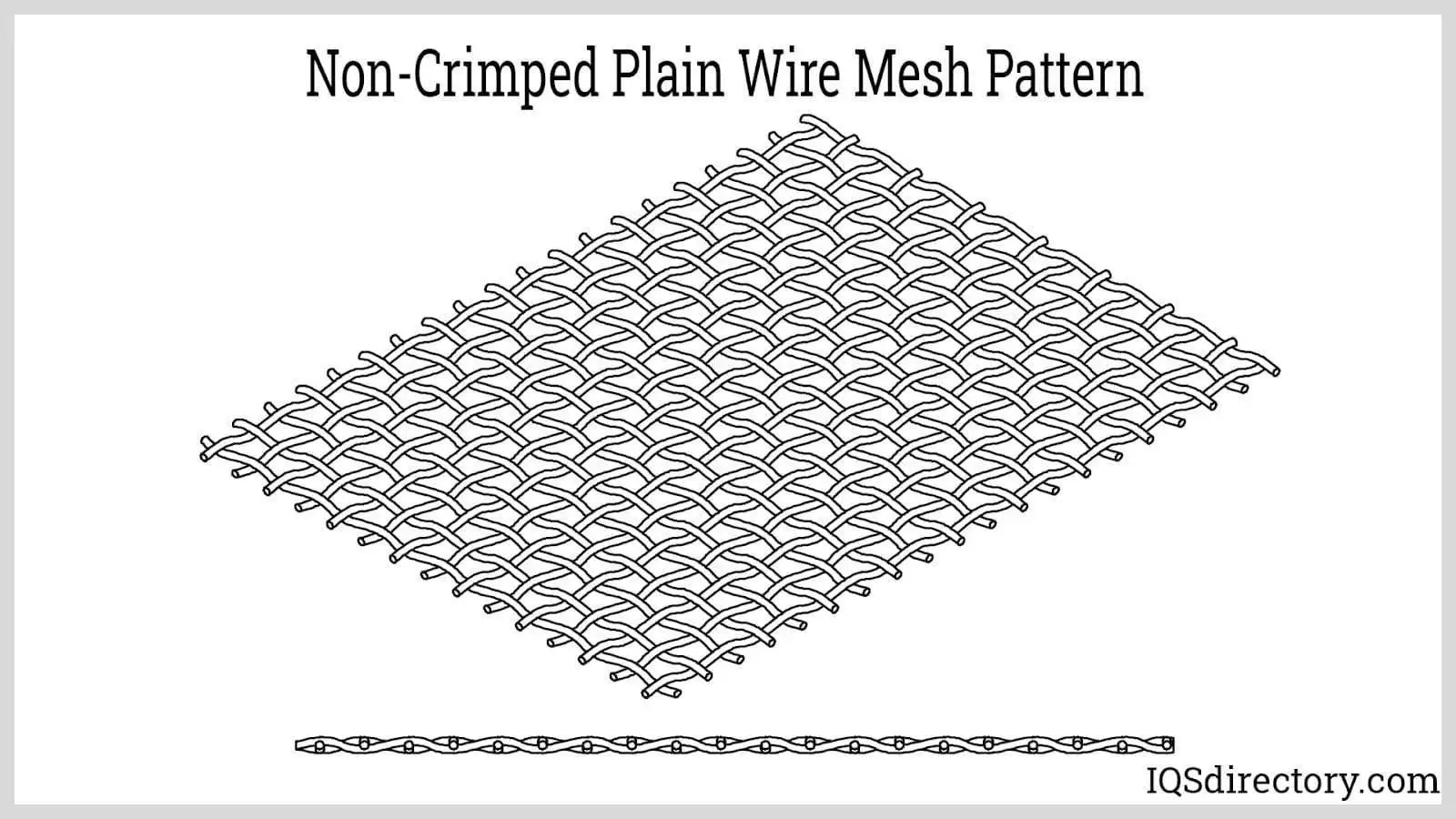

Non-Crimped Wire

Non-crimped or plain wire mesh is woven using basic over-and-under techniques, producing a smooth, uncomplicated surface. This approach yields high mesh count patterns, often featuring a 3×3 weave or finer, prevalent in screens such as window or door screens.

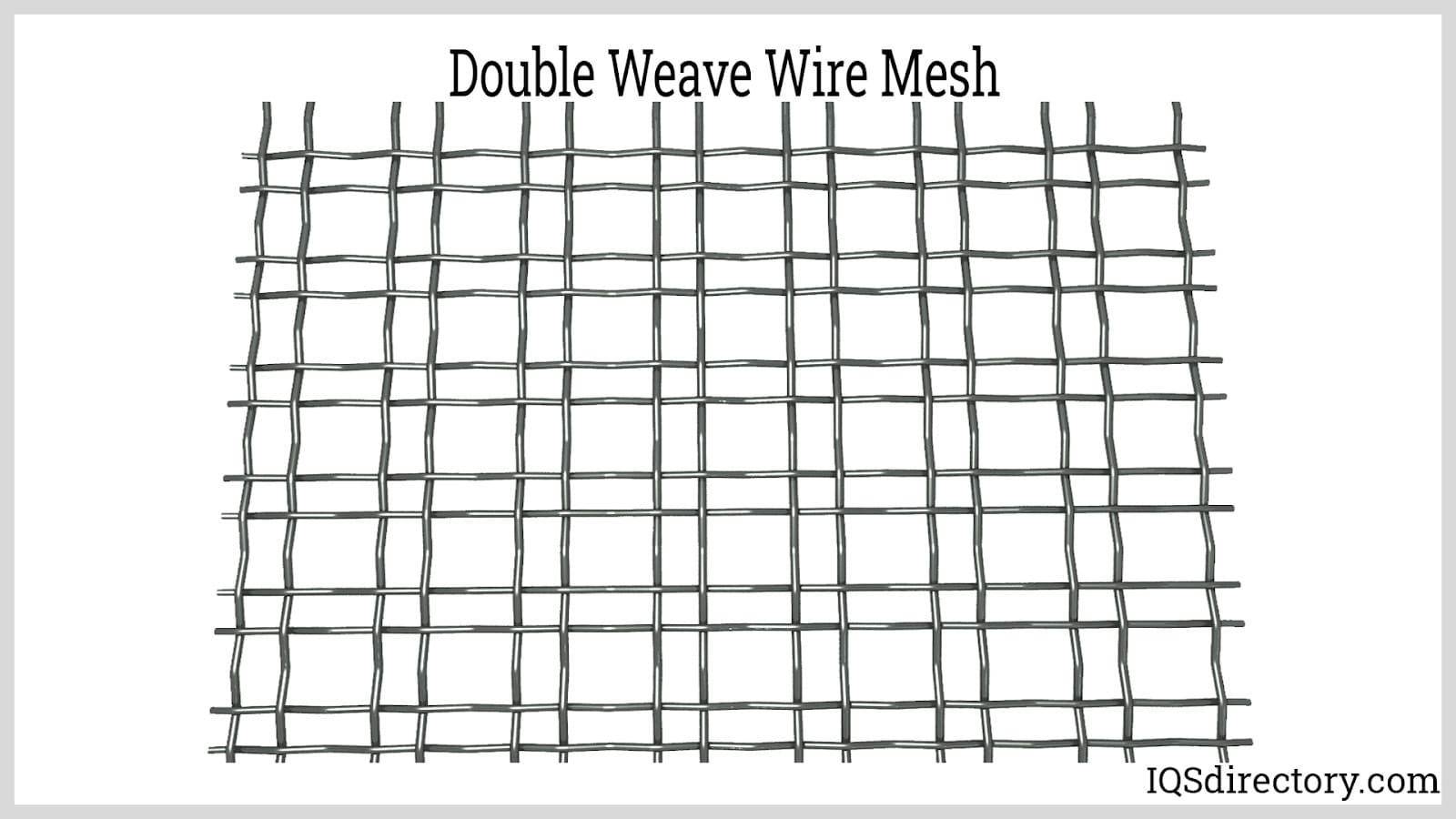

Double Weave Wire Mesh

Double weave wire mesh offers enhanced toughness due to a dual wire weave method. Here, warp wires wrap over two weft wires, making this mesh ideal for rigor-demanding applications like vibrating screens, agriculture, and barbecue screens.

Flat Top Weave Wire Mesh

Flat top weaves pair non-crimped warp wires with crimped weft wires, creating a lockable mesh that remains smooth, reducing friction and abrasion potential. Ideal for architectural and structural needs, it’s favored in applications like vibrating screens for durability and efficiency.

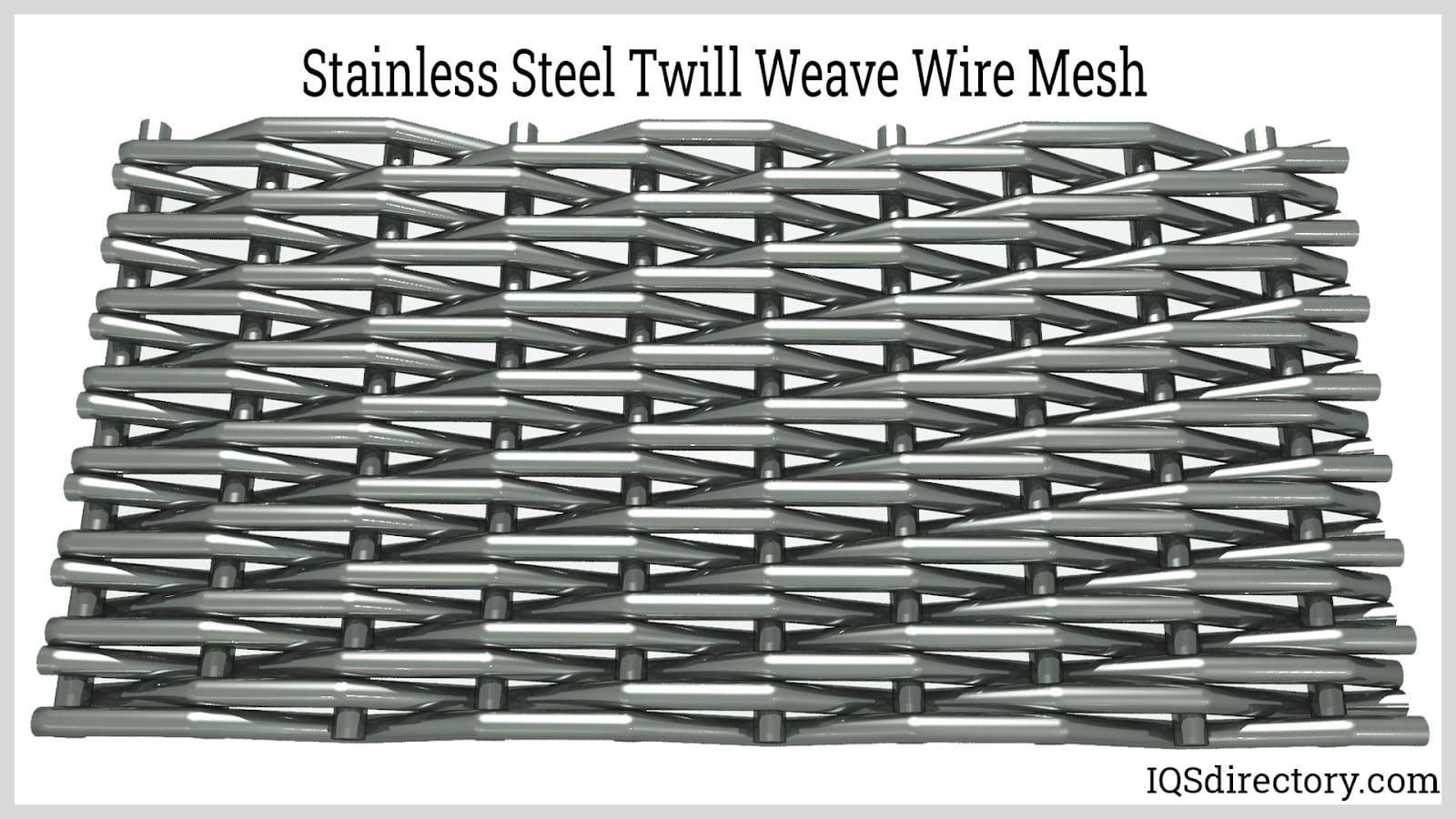

Twill Weave Wire Mesh

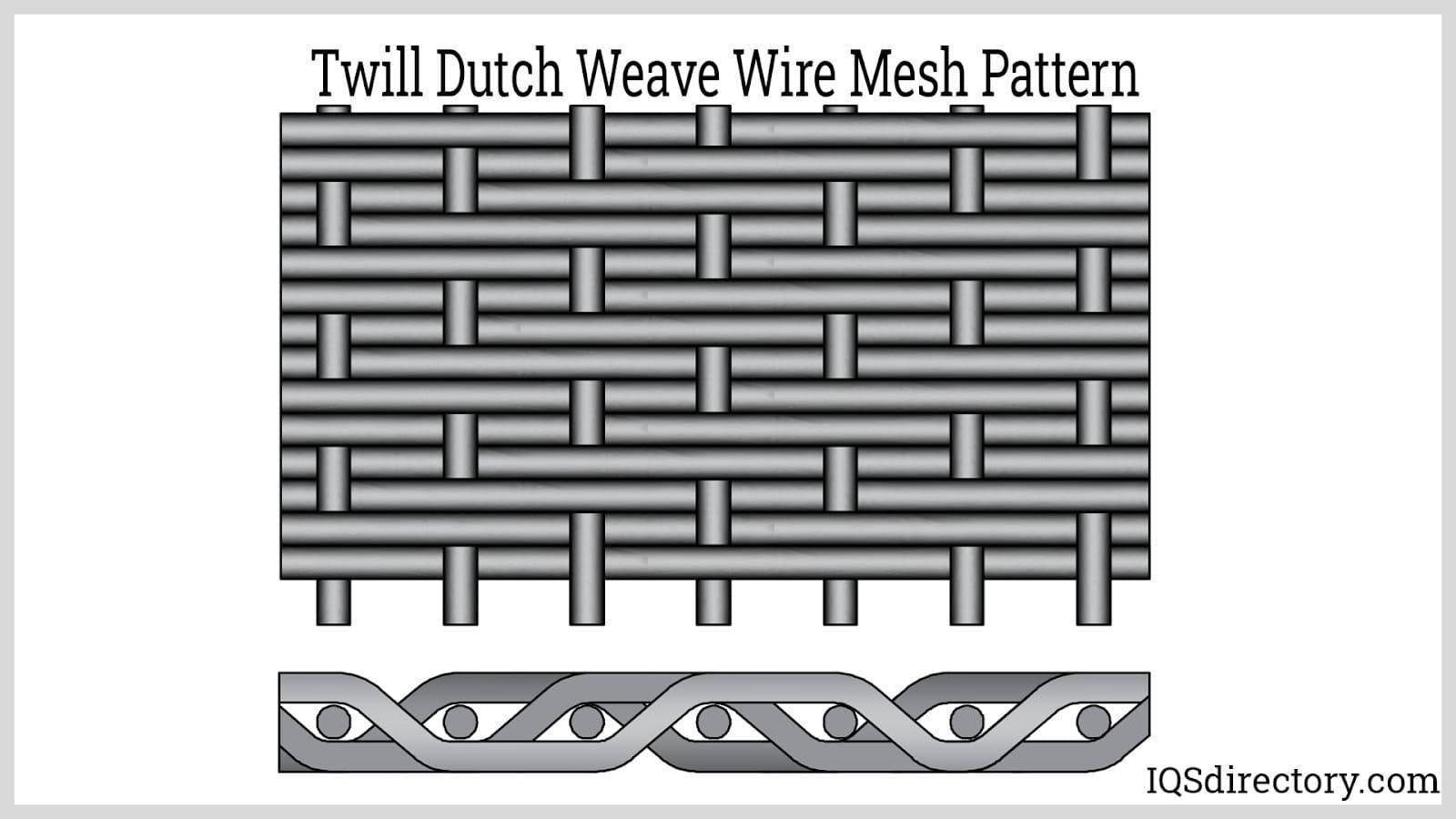

The twill weave pattern involves alternating warp wire over-under placement across two weft wires, creating a diagonal design with enhanced strength and durability. This weave is adept at supporting heavier loads and is fundamental in filter, colander, shielding, and insect screen fabrication, using corrosion-resistant

stainless steel grades 304 and 316.

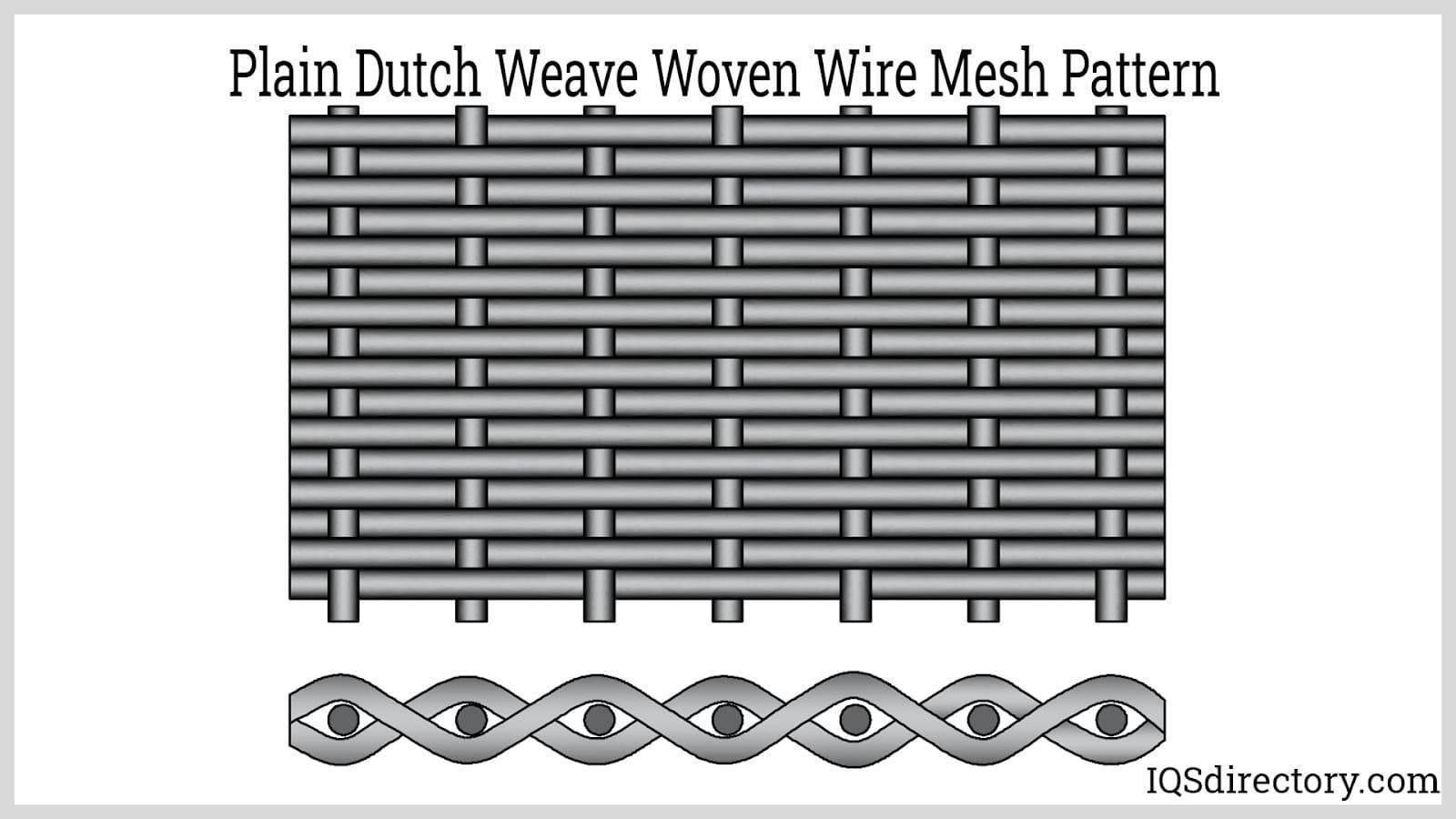

Dutch Weave Wire Mesh

Dutch weave wire mesh differs with varied wire diameters for warp and weft, ensuring greater tensile strength and superior filtration. Dutch weaves, crafted in plain or twill patterns, offer strength and filter efficacy.

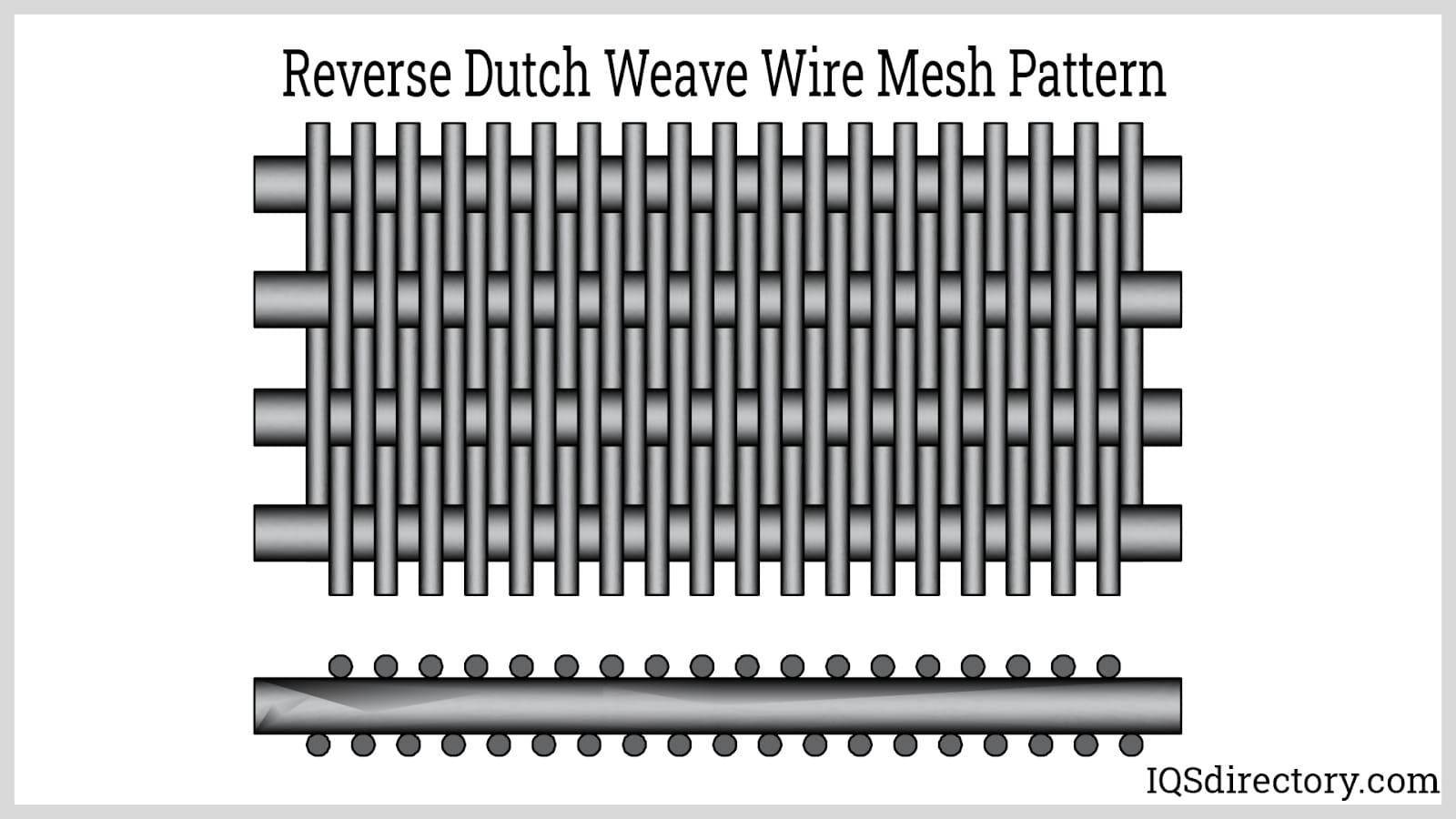

Reverse Dutch Woven Wire — Similarly executed to plain Dutch weave, reverse Dutch applies an inverse of warp and weft positioning, resulting in enhanced warp strength for acoustic, mechanical strength, and filtering use in applications.

Off Count Wire Mesh

Off count wire mesh features a different number of openings in horizontal and vertical directions, forming a rectangle instead of squares, making it invaluable for sifting and sizing operations even when some deviation is accepted.

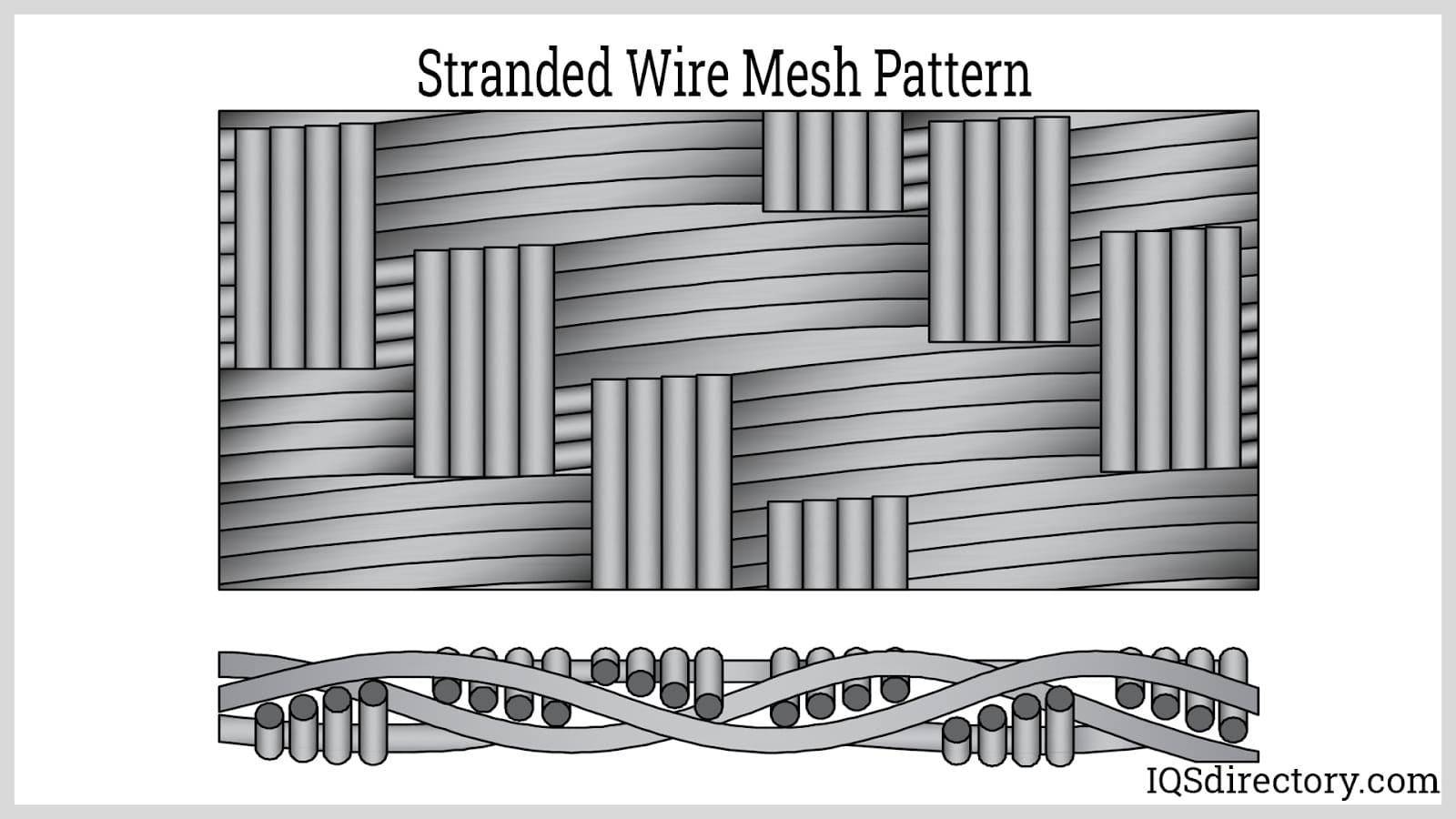

Stranded Weave Wire Mesh

Stranded weave mesh uses small bundles of weft and warp wires in a dense square pattern for strength and compactness, essential for microfiltration applications.

Mesh Count Details

An essential concept in wire mesh, mesh count signifies the number of openings in a linear inch. Measured by counting openings from wire center to wire center, it’s expressed simply, such as 4×4 or 20×20, indicating openings per inch.

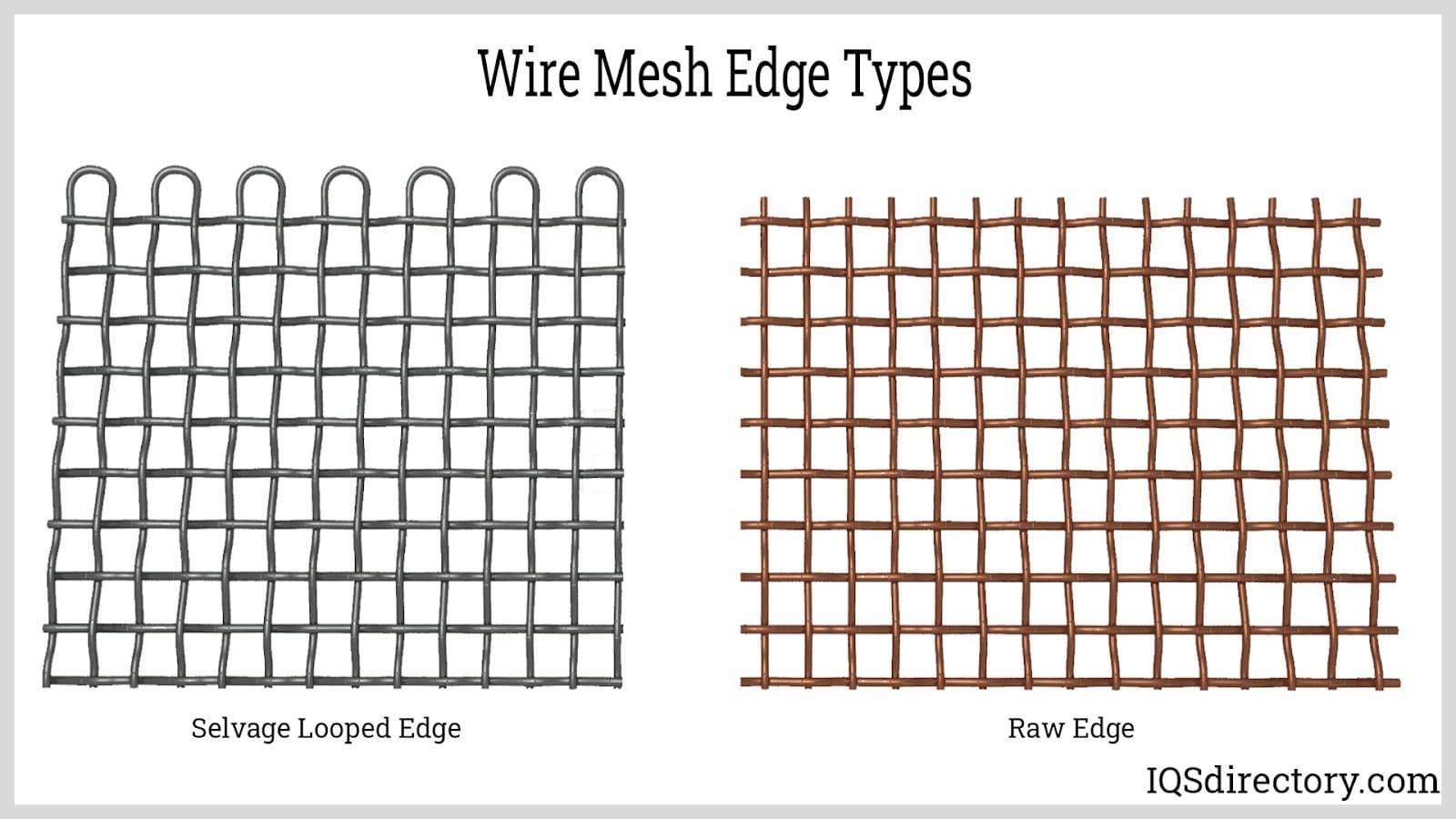

Edge Types in Wire Mesh

Wire mesh edges are either raw or selvage. Raw edges show exposed weft wires, while selvage edges have a finished border ensuring stability and safer handling. Looping at the perimeter accomplishes selvage edges, enhancing mesh durability.

What Types of Wire Are Used to Make Wire Mesh?

Wire mesh is mainly made from wire, which can be made from different types of metals. These wires come in various thicknesses, affecting the size and strength of the mesh and what it can be used for. The thickness of the wire is important: thicker wires (lower numbers) are stronger, while thinner wires (higher numbers) are often used for things like filters or screens for insects. The combination of the number of wires per area, the thickness of the wire, and the size of the openings all help define the type of mesh and its uses in different industries.

Plain and crimped wire mesh usually have wires that are all the same size, making them strong and even. In contrast, special types of wire mesh, like Dutch woven wire mesh, use different wire sizes to allow for very fine filtering and higher density. Stranded wire mesh is made of many thin wires twisted into bundles, which makes it more flexible and durable in tough conditions.

The material of the wire affects its chemical resistance, durability, and uses. Industrial wire is made by pulling raw metal through precise tools to create different shapes like round, square, hexagonal, or rectangular. Custom wire designs, like expanded or welded mesh, are tailored for specific industries and needs.

Carbon Steel in Wire Mesh

Carbon steel wire mesh, also known as plain steel wire mesh, is a popular choice for industrial and architectural uses. Made mostly of iron with a small amount of carbon, it is affordable and strong. It is widely used in construction, mining, security, filtration, machine protection, and infrastructure. Its versatility comes from surface treatments like zinc coating for corrosion resistance or powder coating for durability and design.

Carbon steel wire is a cost-effective and durable choice for indoor or controlled environments. For better weather resistance and a longer lifespan in outdoor settings, hot-dipped galvanized or PVC-coated wire mesh is preferred.

Stainless Steel in Wire Mesh

Stainless steel wire mesh is known for its strength, durability, and corrosion resistance, making it ideal for industries like pharmaceuticals, chemicals, food processing, marine, and architecture. Its resistance to rust and chemicals makes it suitable for filtration, sifting, fencing, and security screens in demanding environments.

When selecting stainless steel wire mesh, users should consider mesh opening size, wire diameter, and grade based on the level of corrosion resistance, load-bearing capacity, and hygiene requirements demanded by their intended use.

Aluminum Wire in Wire Mesh

Aluminum wire mesh is valued for its lightweight, malleable, corrosion-resistant, and cost-effective nature, making it the most popular non-ferrous wire mesh material. It is widely used in insect screens, architectural panels, and filtration, with its natural oxide layer protecting against rust and weathering, ideal where appearance and lightness are important. While pure aluminum (grade 1000 series) is rarely used unalloyed, it is often alloyed with copper, magnesium, zinc, or silicon to improve strength and workability.

Key aluminum wire mesh alloys include 1350 (high electrical conductivity), 5056 (corrosion resistance for marine/industrial use), and 6061 (strength and weldability for structural applications). Alloy choice impacts tensile strength, formability, and longevity.

Aluminum mesh is lightweight, easy to work with, and customizable, ideal for practical and design-focused uses. Its non-magnetic property is key for EMI shielding applications.

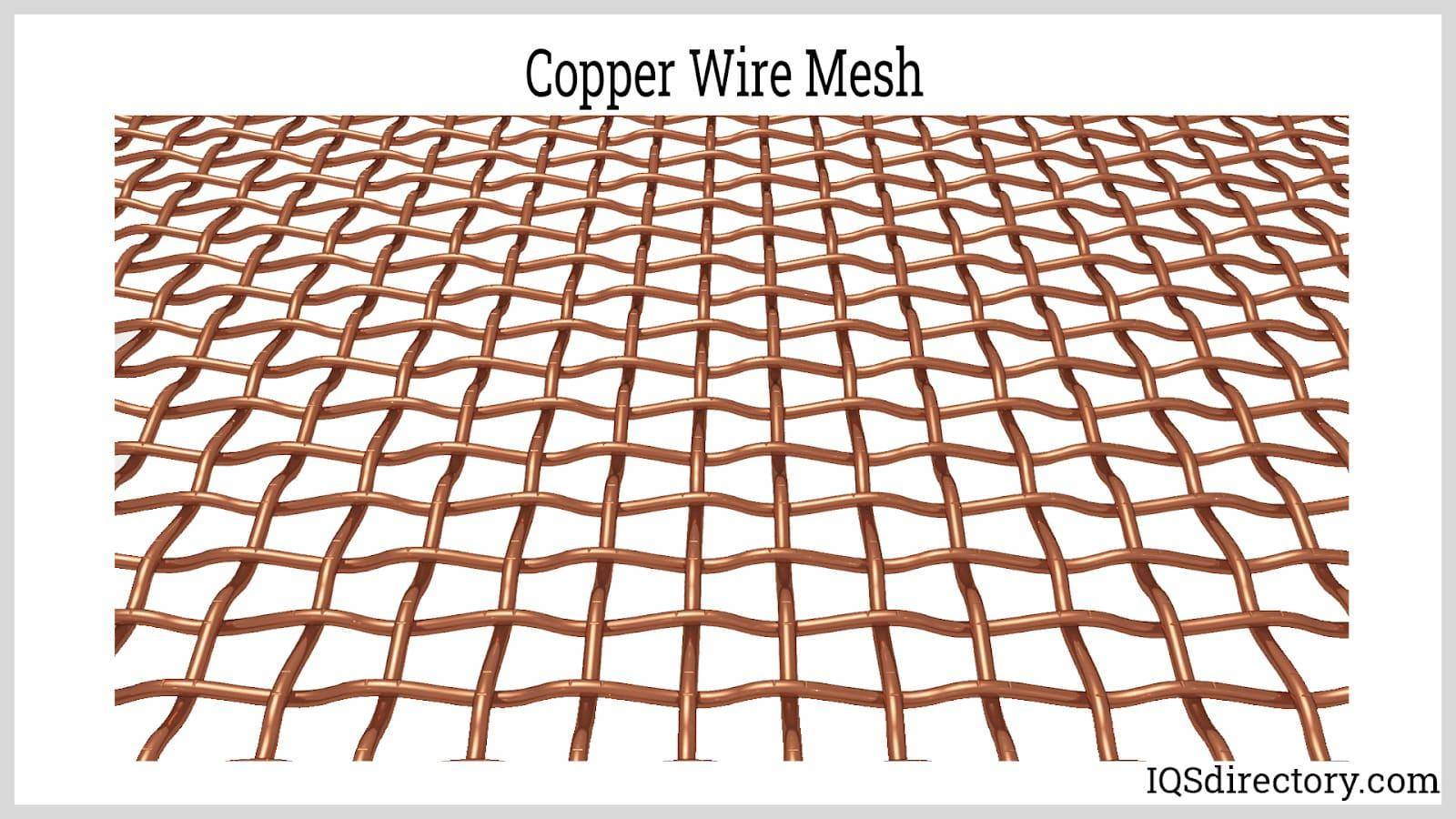

Copper in Wire Mesh

Copper wire mesh is known for its ductility, excellent electrical and thermal conductivity, and antimicrobial properties. These qualities make it ideal for EMI/RFI shielding, Faraday cages, battery current collectors, and specialized lab or filtration uses. It’s commonly used in electronics, telecommunications, scientific research, and architectural restoration for both functional and aesthetic purposes.

Most copper mesh is made from copper alloys to enhance strength and durability. Pure copper, though used sometimes, patinas when exposed to air, changing from salmon-red to dark brown, and finally to blue-green verdigris. To prevent tarnishing and oxidation, protective coatings are applied to maintain its appearance and conductivity.

Brass in Wire Mesh

Brass wire mesh, an alloy of copper and zinc, is known for its high tensile strength, abrasion resistance, and appealing golden color. Referred to as 270 yellow brass (65% copper, 35% zinc) or 260 high brass (70% copper, 30% zinc), it combines durability with aesthetics, making it ideal for tough and decorative environments.

Brass mesh is used for architectural details, grilles, screens, and artistic installations. Its non-sparking quality makes it ideal for filtration in hazardous atmospheres.

Bronze in Wire Mesh

Bronze wire mesh, an alloy of 90% copper and 10% zinc or tin, offers great durability, malleability, and high corrosion resistance, especially in marine environments. It is harder and less malleable than brass, making it suitable for applications requiring strength and longevity. Commonly used in industrial filtration, marine projects, architecture, pest control, and restoration, bronze mesh is valued for its performance and warm finish.

In addition to common metals, custom wire mesh can be made from advanced materials like titanium (lightweight and biocompatible for aerospace and medical), Hastelloy (corrosion resistant for chemical use), Monel 400 (marine applications), nichrome (high-temperature resistance), Inconel (superalloy heat and corrosion resistance), and tungsten (high strength and melting point). Any ferrous or non-ferrous metal, including exotic alloys, can be transformed into precision-engineered wire mesh for various specifications.

Choosing the right wire for mesh depends on mechanical needs, environment, budget, and purpose—whether for screening, filtration, security, or decor. Consult a trusted supplier to ensure the best material, specification, and design for your project.

What are the uses for wire mesh?

Wire mesh is versatile and widely used in various applications, including protective shielding, filtration, separation systems, and railing support in industrial settings. It’s essential in wastewater treatment, petrochemical plants, and juice production filtration systems.

Wire mesh has long been used for various commercial purposes, providing insect protection and constructing animal enclosures. It appears in screen doors, window screens, screen partitions, and decorative screens.

Industries that commonly rely on wire mesh include:

Wire mesh is used in both commercial and residential settings for various applications, including:

What are the benefits of wire mesh?