Key Standard-Setting Institutions for Metal Wire Mesh

We adhere to the highest industry standards, ensuring our wire mesh products meet stringent requirements for quality, safety, and performance. Below are some of the key standard-setting institutions that guide our manufacturing processes and product development.

Explore their websites to learn more about the specific standards we follow.

Technical Information

Barbed

ASTM A121-22

Standard Specification for Metallic-Coated Carbon Steel Barbed Wire

ASTM F1379-95(2022)

Standard Terminology Relating to Barbed Tape

ASTM F1665-08(2022)

Standard Specification for Poly(Vinyl Chloride) (PVC) and Other Conforming Organic Polymer-Coated Steel Barbed Wire Used With Chain-Link Fence

ASTM F1910-98(2022)

Standard Specification for Long Barbed Tape Obstacles

Chain Link Fence

ASTM A392-11a(2017)

Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric

ASTM A491-11(2022)

Standard Specification for Aluminum-Coated Steel Chain-Link Fence Fabric

ASTM F552-14(2023)

Standard Terminology Relating to Chain Link Fencing

ASTM F668-17(2022)

Standard Specification for Polyvinyl Chloride (PVC), Polyolefin and Other Polymer-Coated Steel Chain Link Fence Fabric

ASTM F934-96(2022)

Standard Specification for Standard Colors for Polymer-Coated Chain Link Fence Materials

ASTM F1183-96(2022)

Standard Specification for Aluminum Alloy Chain Link Fence Fabric

ASTM F1345-10a(2023)

Standard Specification for Zinc-5 % Aluminum-Mischmetal Alloy-Coated Steel Chain-Link Fence Fabric

ASTM F1553-11(2022)

Standard Guide for Specifying Chain Link Fence

Expanded Metal

Fences

BS EN 10223

Steel wire and wire products for fencing and netting

BS 1722

Fences

ASTM A116-22

Standard Specification for Metallic-Coated, Steel-Woven Wire Fence Fabric

ASTM A390-06(2021)

Standard Specification for Zinc-Coated (Galvanized) Steel Poultry Fence Fabric (Hexagonal and Straight Line)

ASTM F3342-19

Standard Guide for Temporary Fence Applications for Construction Sites

Metal Bar Grating

Perforated Metal

ASTM E323-11(2021)

Standard Specification for Perforated-Plate Sieves for Testing Purposes

ASTM E454-12(2021)

Standard Specification for Industrial Perforated Plate and Screens (Square Opening Series)

ASTM E674-12(2021)

Standard Specification for Industrial Perforated Plate and Screens (Round Opening Series)

Welded Wire Mesh / Cloth

ASTM F2453/F2453M-14(2025)

Standard Specification for Welded Wire Mesh Fence Fabric (Metallic-Coated or Polymer Coated) for Meshes of 6 in.2 [3871 mm2] or Less, in Panels or Rolls, with Uniform Meshes

ASTM F2919/F2919M-12(2025)

Standard Specification for Welded Wire Mesh Fence Fabric (Metallic-Coated or Polymer Coated) with Variable Mesh Patterns or Meshes Greater than 6 in.2 [3871 mm2] in Panels

ASTM A740-21

Standard Specification for Hardware Cloth (Woven or Welded Galvanized Steel Wire Fabric)

ASTM A810-01(2019)

Standard Specification for Zinc-Coated (Galvanized) Steel Pipe Winding Mesh

ASTM A1064/A1064M-24

Standard Specification for Carbon-Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete

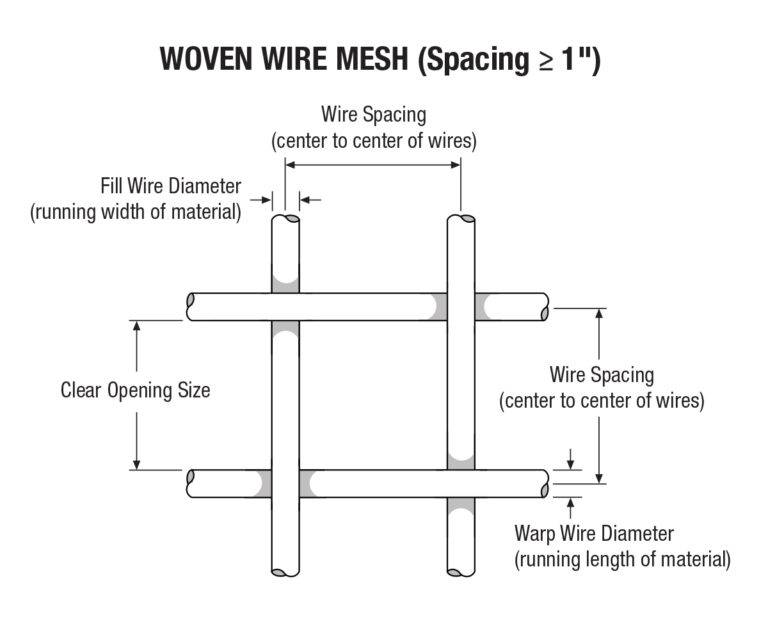

Woven Wire Mesh / Cloth

ASTM E11-24

Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves

ASTM E2016-22

Standard Specification for Industrial Woven Wire Cloth

ASTM E2814-22

Standard Specification for Industrial Woven Wire Filter Cloth

ASTM A740-21

Standard Specification for Hardware Cloth (Woven or Welded Galvanized Steel Wire Fabric)

ASTM A810-01(2019)

Standard Specification for Zinc-Coated (Galvanized) Steel Pipe Winding Mesh

ASTM C1032/C1032M-24

Standard Specification for Woven Wire Plaster Base

ASTM A975-24

Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With Polymer Coating)

Wire

CQI Manuals

Customer Focus:

- Prioritize customer needs and expectations.

- Use customer feedback to drive improvements.

Employee Involvement:

- Engage all employees in quality improvement efforts.

- Foster a culture where everyone contributes to quality.

Process-Centric Approach:

- View activities as interconnected processes.

- Optimize and align processes to achieve better outcomes.

Data-Driven Decision Making:

- Base decisions on accurate and relevant data.

- Use statistical tools to analyze and interpret data.

Systematic Approach to Improvement:

- Follow structured methodologies like Plan-Do-Check-Act (PDCA).

- Implement iterative cycles of planning, executing, reviewing, and refining.

Integrated System:

- Ensure all components of the organization are aligned towards quality goals.

- Promote a holistic approach to quality management.

Sustainability:

- Focus on long-term improvements rather than quick fixes.

- Ensure changes are sustainable and continuously beneficial.

Plan-Do-Check-Act (PDCA):

- Plan: Identify an area for improvement and develop a plan.

- Do: Implement the plan on a small scale.

- Check: Evaluate the results of the implementation.

- Act: If successful, implement on a larger scale; if not, refine and repeat.

Six Sigma:

- A method that uses statistical tools to identify and eliminate defects.

- Focuses on reducing variability and improving process capability.

Lean:

- A methodology that aims to maximize value by eliminating waste.

- Enhances efficiency and effectiveness in processes.

Total Quality Management (TQM):

- An organization-wide approach to embedding quality in every aspect.

- Emphasizes customer satisfaction, employee involvement, and continuous improvement.

Benchmarking:

- Comparing organizational processes and performance metrics to industry best practices.

- Identifying areas where the organization can improve.

Assessment:

- Conduct a thorough evaluation of current processes and performance.

- Identify strengths, weaknesses, and areas for improvement.

Goal Setting:

- Define clear, measurable quality improvement goals.

- Align goals with organizational objectives and customer needs.

Training and Development:

- Train employees on CQI principles, tools, and techniques.

- Develop skills necessary for quality improvement.

Process Mapping and Analysis:

- Document and analyze existing processes to identify inefficiencies.

- Use tools like flowcharts and cause-and-effect diagrams.

Implementing Improvements:

- Apply chosen CQI methodologies to implement improvements.

- Pilot changes on a small scale before full implementation.

Monitoring and Evaluation:

- Continuously monitor processes and measure outcomes.

- Use key performance indicators (KPIs) to track progress.

Feedback and Refinement:

- Collect feedback from stakeholders and employees.

- Refine and adjust processes based on feedback and performance data.

- Enhanced Quality: Improved products and services meet or exceed customer expectations.

- Increased Efficiency: Streamlined processes reduce waste and increase productivity.

- Customer Satisfaction: Higher quality and reliability lead to greater customer loyalty.

- Employee Engagement: Involving employees in improvement efforts boosts morale and job satisfaction.

- Competitive Advantage: Continuous improvements help organizations stay ahead in the market.