- Home

- Products

- Woven Wire Fence

- Wire & Coating

Wire Tensile Strength

Understanding Wire Tensile Strength

Agricultural fencing is made of either low carbon or high tensile wire and it is our job to make sure you know the difference between the two before you select a fence for your next project. Knowing the differences in tensile strength and determining which type of wire is right for your project will save time and money on labor and materials.

High Tensile Wire

High tensile fencing is made from high carbon steel with a carbon content of .28%, the higher the carbon content, the stronger the wire will be. High carbon wire will stretch 4% before breaking and will not sag as much as low carbon wire. This type of wire is easy to install and requires little maintenance even in harsh weather conditions. High tensile wire is often used to fence off livestock that are nearby highways as it is strong enough to withstand the force of a car skidding into it.

Advantages of installing high tensile wire:

Low Carbon Wire

Wire used in traditional agricultural fencing is made of low carbon steel with a maximum carbon content of .10 percent. Low carbon wire is used to construct products like conventional field fence and barbed wire. It is not as durable as high tensile wire, making low carbon wire prone to sagging, stretching and elongation over time. Be mindful of maintenance time and costs when working with it.

Advantages of installing low carbon wire:

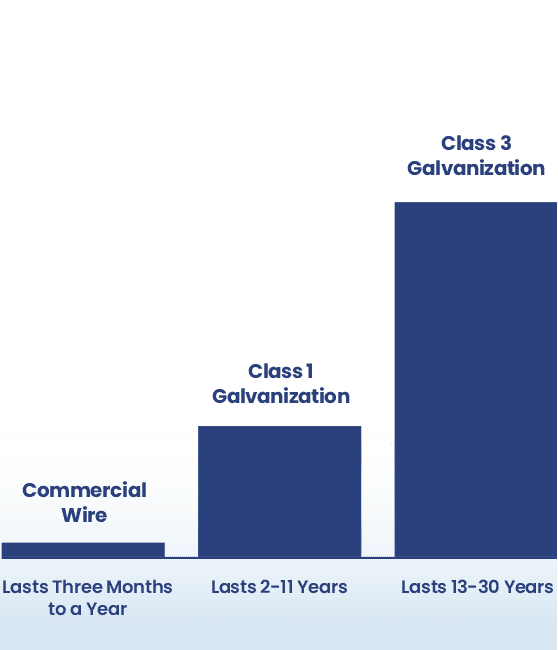

Understanding Wire Coatings

Selecting a wire with the proper coating is essential to protecting your fence from harsh environmental elements including humidity, sand, soil chemicals, fertilizer, salt, pollution and acid rain.

Commercial wire has no standard minimum coating and is not recognized by ASTM. The galvanization will last approximately three months to a year before signs of rust begin to appear.

Class 1 galvanization is the most economical protective coating used on standard fence wire. It is considered a basic coating and will last two to 11 years in non-coastal climates.

Class 3 galvanization is the standard on all products. It is approximately 2.5 times thicker than the standard Class 1 coating and can be expected to last 13 to 30 years before rust. All Class 3 Products meet or exceed ASTM A-121 standards.